News

News

- Excavator steering system anatomy training desk

- Hydraulic front hanging mechanical experimental device

- Water pump performance experimental device

- Contact oxidation pool training desk

- Drinking water treatment process training desk

- Reverse osmosis membrane training

- Softness and salt removal experimental device

- Salvation tank experimental device

- Aerobic biological treatment training device

- Bio -turntable principle experimental device

- Lucky ratio blocking test device

- Socci condiment training desk

- Industrial wastewater treatment training desk

- Industrial wastewater treatment process simulation experimental device

- CNC milling machine installation and maintenance training table

- CNC Machining Center Maintenance and Processing Technical Experimental Desk

- AC Voltage Merragatory System Electrical Experiment Device

- Solar power generation experimental device

- Electrical experimental device of ship anchor machine

- Worker Electrical Engineering Technology Training Device

Contact us

WeChat:15372285263

Phone:15372285263

WhatsApp:15372285263

Address:Building 3, No. 7 Longyuan Road, Shuige Industrial Park, Liandu District, Lishui City, Zhejiang Province

News

DC motor and control teaching experimental desk

Author:

Time:2023-12-27

Hits:

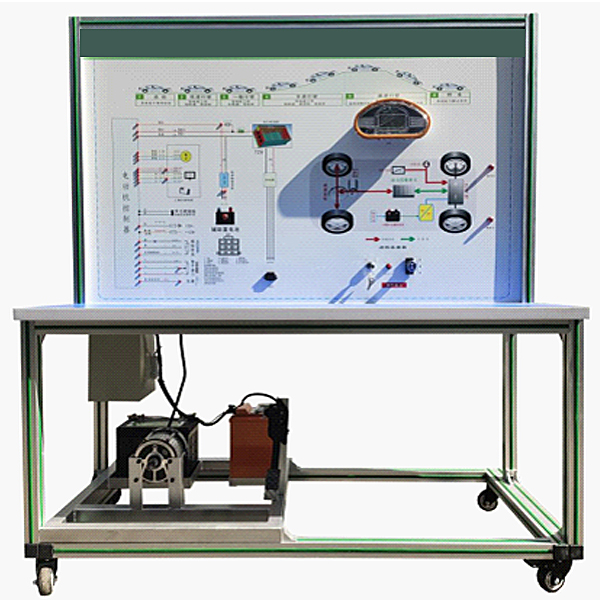

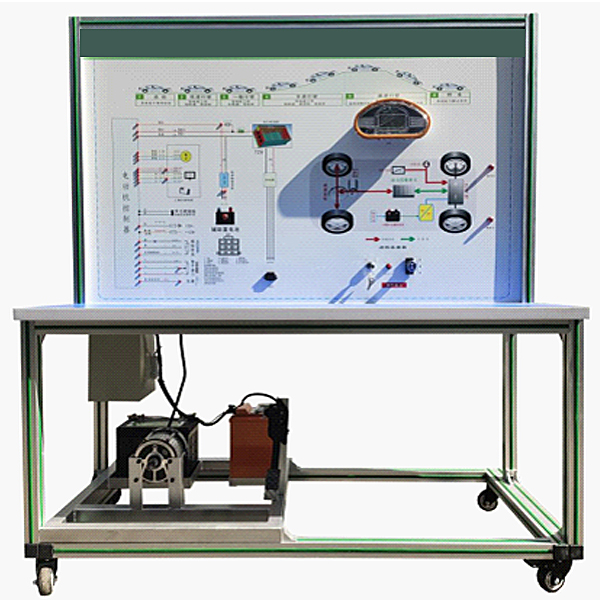

DC motor and control teaching experimental desk,Mechanical Principles Comprehensive Experimental Piece

1. Product composition

DC motor and control teaching experimental desk,Mechanical Principles Comprehensive Experimental Piece

1. Product composition

It is m--nly composed of automotive brush -free DC motors, motor controllers, gear switches, accelerated pedals, ignition switches, power and fault setting systems.

2. Product function

1. Cognition of automotive brush -free DC motors and controllers;

2. The structure and principles of car brushless DC motors and controllers;

3. The manifestation of the driver's intention and the operation of permanent magnet motor;

4. Settings and assessment of common faults;

5. Equipped with a complete experimental manual.

3. Product specifications

1. The shape size is 1240 × 600 × 1700mm;

2. Power: 220VAC/50Hz;

3. The rated power of the motor: 1kW;

4. Motor rated speed: 3000rpm;

5. Motor working voltage: 72VDC;

6. The upper part of the box is formed as a whole, and the surface is rust -proof and p--nted; the lower part is welded by 40*40 square tube;

7. Use the UV tablet inkjet panel with a thickness of not less than 4mm. The color circuit diagram is not refunded and wear -resistant;

8. Two thousand -or two -directed foot wheels are installed at the bottom, equipped with brakes to facilitate the movement and fixing of the device.

9. Machinery assembly and fitter assembly virtual simulation software: This software is developed based on Unity3D. It can select 6 -level image quality. It has the design and virtual disassembly of the reducer and shaft structure, the design and simulation of common mechanical institutions, institutional resource libraries, institutional resource libraries. Typical mechanical institutions (virtual disassembly of gasoline engines), software is an overall software, which cannot be separate resources.

A. Turbine design and virtual disassembly interface can be selected from turbine sn--l pole cone gear reducer, second -level pilot gear reducer, conical cylindrical gear reducer, coaxial cylindrical gear reducer, cone gear reducer, first -class cylindrical, first -class cylindrical, Gear reducer.

DC motor and control teaching experimental desk,Mechanical Principles Comprehensive Experimental Piece

1. Technical requirements

1. Experimental items: (73 experiments in total)

1) 14 types of flat link mechanism

2) 7 camsi mechanisms

3) 2 types of fixed axis gear mechanism

4) 1 type of 2K-H weekly rotor system

5) 1 type of needle wheel mechanism

6) 4 types of spiny wheel mechanism

7) Two types of grooves mechanism

8) 1 type of incomplete gear intermittent movement mechanism

9) Graduation of the Gear Gear Institution Series Experiment

① Gradually open the line to form a demonstration experiment (4 items)

② Fancheng Law Graduation Experimental Experiment (Fan Chengfa Gradually Open the Line tooth Formation Experiment) (6 items)

③ Graduation of a str--ght -tooth cylindrical gear geometric parameter measurement experiment:

a) Standard str--ght tooth cylindrical geometric geometric parameters test experiments (8 items)

b) Term of geometric parameters of str--ght tooth cylindrical gears (8 items)

c) Unde -variable str--ght -tooth cylindrical geometric parameter measurement experiment (8 items)

D) Graduation line str--ght tooth cylindrical gear transmission meshing test experiment (4 items)

10) Determine the type and benchmark system of holes and shafts, and select the processing accuracy level

11) Surveying and mapping parts diagram and assembly diagram

12) Drawing the processing process of parts and assembly processes

- Previous:The bolt group connects the experiment table

- Next:Charging pile and charging training device

Recommended information

Recommended Products