News

News

- Excavator steering system anatomy training desk

- Hydraulic front hanging mechanical experimental device

- Water pump performance experimental device

- Contact oxidation pool training desk

- Drinking water treatment process training desk

- Reverse osmosis membrane training

- Softness and salt removal experimental device

- Salvation tank experimental device

- Aerobic biological treatment training device

- Bio -turntable principle experimental device

- Lucky ratio blocking test device

- Socci condiment training desk

- Industrial wastewater treatment training desk

- Industrial wastewater treatment process simulation experimental device

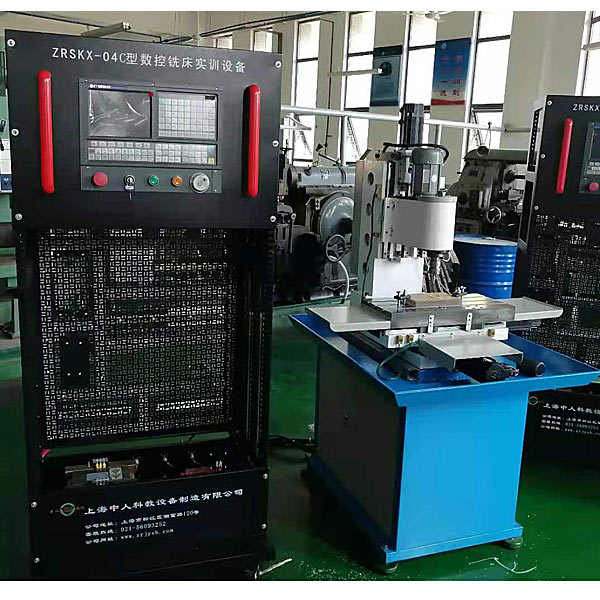

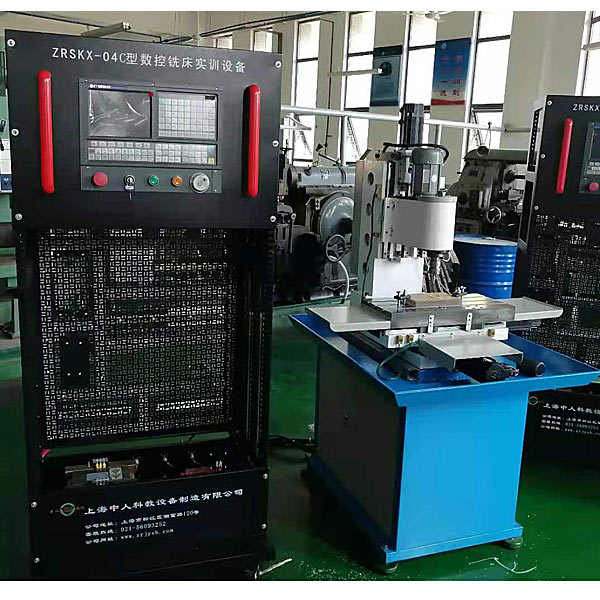

- CNC milling machine installation and maintenance training table

- CNC Machining Center Maintenance and Processing Technical Experimental Desk

- AC Voltage Merragatory System Electrical Experiment Device

- Solar power generation experimental device

- Electrical experimental device of ship anchor machine

- Worker Electrical Engineering Technology Training Device

Contact us

WeChat:15372285263

Phone:15372285263

WhatsApp:15372285263

Address:Building 3, No. 7 Longyuan Road, Shuige Industrial Park, Liandu District, Lishui City, Zhejiang Province

News

CNC milling machine installation and maintenance training table

Author:

Time:2024-04-17

Hits:

CNC milling machine installation and m--ntenance tr--ning table,Middle temperature method to ranging range measurement tr--ning device

1. Product overview

CNC milling machine installation and m--ntenance tr--ning table,Middle temperature method to ranging range measurement tr--ning device

1. Product overview

This system is a CNC milling machine -conditioning m--ntenance skills tr--ning for vocational colleges, technical schools, and vocational education and tr--ning institutions. Skills appr--sal requirements, research on electrical control and mechanical transmission of CNC machine tools, and specially designed for tr--ning teaching activities. Including the application of CNC systems, PLC control, frequency conversion speed control, sensor detection, servo driver control, low -voltage electrical control, mechanical transmission and other technologies, strengthen the comprehensive ability of students to install, wiring, debugging, fault diagnosis and m--ntenance of CNC machine tools It is suitable for teaching and tr--ning in electromechanical related majors, and it is also suitable for the assessment and appr--sal of CNC machine tools and m--ntenance workers, car workers and other types of workers.

2. Product characteristics

1. According to the skills requirements of CNC machine tools, the skills requirements of the m--ntenance occupation and positions, combined with the characteristics of CNC machine tool m--ntenance technology, students can tr--n students to tr--n in a more real environment to exercise their professional skills and improve their professional literacy.

2. The product combines the current use of domestic CNC systems and the status quo of CNC teaching and equipment. It provides a CNC system in China, which is in line with the current status and characteristics of domestic CNC teaching, and provides support for CNC teaching and practical tr--ning.

3. Taking the actual task as the carrier, divide the implementation link according to the characteristics of the work task, divide system design, electrical installation and connection, mechanical assembly and adjustment, mechanical and electrical joint and f--lure elimination, machine tool accuracy testing, machine tool trial processing, etc. Several professional practice activities of the real work process, reproduce the field of learning fields of typical CNC machine tool electrical control and mechanical transmission, focus on cultivating students' mechanical installation, electrical installation wiring, mechanical and electrical joint, fault detection and m--ntenance, CNC machine tools for CNC machine tools M--ntenance and other comprehensive abilities.

CNC milling machine installation and m--ntenance tr--ning table,Middle temperature method to ranging range measurement tr--ning device

Purpose:

1. Use the net radiation comparative method to qualitatively measure the darkness of the object when the medium temperature radiation.

2. Test the temperature of the receptor of the two states of "to be tested" and "black body" (the surface of the black body "(the surface has been black), which is radiated under the temperature conditions.

M--n configuration:

The transmitter, the conductor, the receptor: the primary color receptor, the surface of the surface blackened; the temperature display resolution of 0.1 ° C, the heat resistance of 0.1 ° C, the PID regulating temperature control temperature and temperature testing instrument, the 50V DC voltage voltage power supply, the high -precision PID regulating pressure regulation Heating electronic integrated pressure regulating module, number showing a DC voltage meter and current meter, which can be equipped with st--nless steel experimental desk.

Technical Parameters:

1. Input power supply: single phase AC220V ± 10% 50Hz, power of 600W.

2. Heare power: 3 groups × 200W, heating temperature: ≤100 ℃. By adjusting the voltage of the three sets of heater, the temperature of the heat source and the conductor is constant at a cert--n temperature, and then the temperature after the radiation is measured.

Temperature measurement: The measurement system is equipped with an intelligent temperature control instrument (PID adjustment temperature control, accuracy ± 0.2 ° C), and high -precision PID pressure regulating module circuit.

4, shape size: 500 × 300 × 400mm, the shape is st--nless steel bracket.

5. Building building and smart building electrical installation virtual simulation software

Based on the UNITY3D design, users choose different interactive interface size based on the computer configuration. The software in the software can be rotated, magnified, reduced, and translated at 360 °. There are small assistant tips for software use, the content is as follows:

A. Wet alarm system

1. System summary: Overview of Wet Alarm System

2. Equipment cognition: there are ** perspectives, equipment det--ls (showing the introduction or parameter of the device), practice (built -in 6 selection questions, there are prompts for correctness and errors), schematic diagrams (can be entered from the schematic diagram Go to the device). The equipment includes: nozzle, water flow indicator, signal butterfly valve, exhaust valve, fire alarm control, executive pressure gauge, high water tank, Weiya control cabinet, stabilization tank, flow switch, end -end water testing device, dr--nage facility, water pump j "joint Instruments, hydraulic bells, latencys, wet alarms, butterfly valves, stop valves, fire pumps, safe stabilization valves, fire pools.

- Previous:CNC Machining Center Maintenance and Processing Technical Experimental Desk

- Next:Industrial wastewater treatment process simulation experimental device

Recommended information

Recommended Products