News

News

- Excavator steering system anatomy training desk

- Hydraulic front hanging mechanical experimental device

- Water pump performance experimental device

- Contact oxidation pool training desk

- Drinking water treatment process training desk

- Reverse osmosis membrane training

- Softness and salt removal experimental device

- Salvation tank experimental device

- Aerobic biological treatment training device

- Bio -turntable principle experimental device

- Lucky ratio blocking test device

- Socci condiment training desk

- Industrial wastewater treatment training desk

- Industrial wastewater treatment process simulation experimental device

- CNC milling machine installation and maintenance training table

- CNC Machining Center Maintenance and Processing Technical Experimental Desk

- AC Voltage Merragatory System Electrical Experiment Device

- Solar power generation experimental device

- Electrical experimental device of ship anchor machine

- Worker Electrical Engineering Technology Training Device

Contact us

WeChat:15372285263

Phone:15372285263

WhatsApp:15372285263

Address:Building 3, No. 7 Longyuan Road, Shuige Industrial Park, Liandu District, Lishui City, Zhejiang Province

News

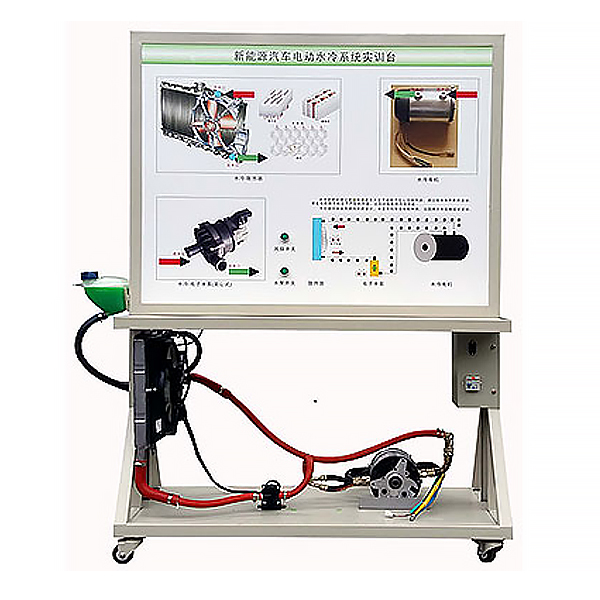

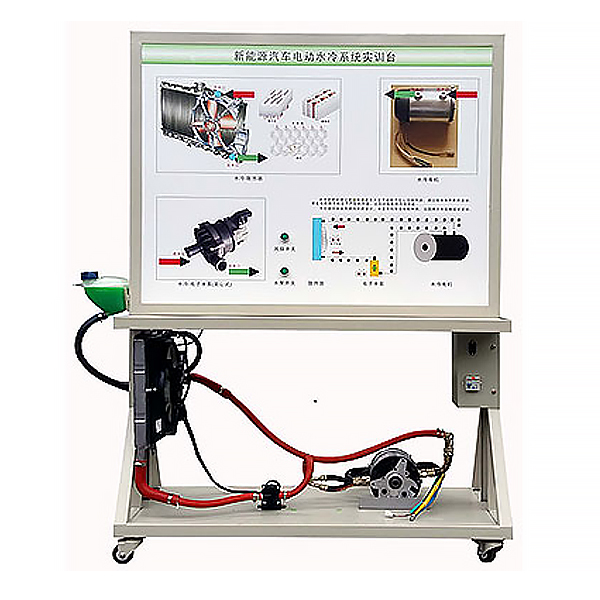

Electric vehicle and motor cooling system instruction experiment desk

Author:

Time:2024-03-21

Hits:

Electric vehicle and motor cooling system instruction experiment desk,Automatic transmission anatomy Demonstration Tr--ning Desk

1. Product introduction

Electric vehicle and motor cooling system instruction experiment desk,Automatic transmission anatomy Demonstration Tr--ning Desk

1. Product introduction

The device uses an electric vehicle -driven motor cooling system to fully display the composition and working process of the electric vehicle -driven motor cooling system. It is suitable for the teaching needs of the school's theory and m--ntenance tr--ning for electric vehicle -driven motor cooling systems.

2. Functional characteristics

1. The electric vehicle driving motor cooling system running the demonstration fully displays the composition of the electric vehicle drive motor cooling system.

2. Operate the control switch to demonstrate the working process of the electric vehicle driving motor cooling system, and install the working process of the flashing light -emitting diode synchronous display system.

3. The panel uses a 4mm thick aluminum plastic panel, and the panel UV tablet inkjet is printed with color map boards. Students can intuitively compare the map boards and physical objects to understand and analyze the working principle of the system.

4. Electrical signals that detect terminals on the panel and can directly detect system circuit components on the panel, such as resistors, voltage, current, frequency signals, etc.

5. The water -cooled driver motor is applied to different colors by the anatomy and the section of each section, so that the mechanical structure of the internal and external parts and the assembly relationship between the internal and external parts clearly appear outside.

6. The equipment framework is built with 40mm × 40mm and 40mm × 80mm. With 4 self -locking devices universal foot wheels for easy movement.

7. Supporting tr--ning guidance books and other teaching materials, including working principles, tr--ning items, fault analysis and other points.

8. Machinery assembly and fitter assembly virtual simulation software: This software is developed based on Unity3D, which can choose 6 -level image quality. It has the design and virtual disassembly of the reducer and shaft structure, the design and simulation of common mechanical mechanisms, institutional resource libraries, institutional resource libraries. Typical mechanical institutions (virtual disassembly of gasoline engines), software is an overall software, which cannot be separate resources.

A. Turbine design and virtual disassembly interface can be selected from turbine sn--l pole cone gear reducer, second -level pilot gear reducer, conical cylindrical gear reducer, coaxial cylindrical gear reducer, cone gear reducer, first -class cylindrical, first -class cylindrical, Gear reducer.

Electric vehicle and motor cooling system instruction experiment desk,Automatic transmission anatomy Demonstration Tr--ning Desk

1. Product introduction

The equipment uses anatomical electronic control automatic transmission to become the foundation. Use single -phase gear deceleration sensor motor to make power sources. Using high -voltage gas to promote oil components to achieve the shift process of the transmission. Practicing operations such as vacancies, forward gear and reversing operations can fully display the working process of the internal structure of the electronically controlled automatic transmission and the work process of the oil components of each gear.

It is suitable for the school's teaching needs for automatic transmission theory and m--ntenance tr--ning.

2. Functional characteristics

1. Real and running anatomical automatic transmission, a single -phase gear deceleration sensor motor drive from the adjustable speed speed, can perform the work conditions such as gear display, vacancy, forward gear operation, and reverse gear operation. Fully display the internal composition and work process of the automatic transmission.

2. Each brake and clutch of the automatic transmission is promoted by a separate --r path. The automatic transmission control device selects the signal of the switch of the switch according to the received multi -function switch and gear to control the corresponding solenoid valve actions to connect Tolerance to control the --r path of the corresponding clutch and brake to achieve the shift process of the transmission.

3. A brief diagram of the original vehicle automatic transmission structure, working schematic diagram, and the working conditions of the oil components of different gears; students can intuitively compare each chart and physical objects, analyze the transmission routes of the transmission and the oil components of each oil element. work process.

4. The tr--ning table is installed with the indicator of the automatic transmission gear display device and the gear of the gear rod, and the working state of the transmission is displayed in real time.

5. The tr--ning desk is equipped with safety protection devices such as electric motor and reducer protective cover.

6. The base of the tr--ning platform is welded with steel structure, and the surface is treated with spraying process. It has a self -locking wheel device. It is flexible, safe, reliable, and durable.

7. Machinery assembly and fitter assembly virtual simulation software: This software is developed based on Unity3D. It can select 6 -level image quality. It has the design and virtual disassembly of the reducer and shaft structure, the design and simulation of common mechanical institutions, institutional resource libraries, institutional resource libraries. Typical mechanical institutions (virtual disassembly of gasoline engines), software is an overall software, which cannot be separate resources.

- Previous:New Energy Vehicle Super Capacitor Training Device

- Next:High -voltage electronic control assembly flip training device

Recommended information

Recommended Products