News

News

- Excavator steering system anatomy training desk

- Hydraulic front hanging mechanical experimental device

- Water pump performance experimental device

- Contact oxidation pool training desk

- Drinking water treatment process training desk

- Reverse osmosis membrane training

- Softness and salt removal experimental device

- Salvation tank experimental device

- Aerobic biological treatment training device

- Bio -turntable principle experimental device

- Lucky ratio blocking test device

- Socci condiment training desk

- Industrial wastewater treatment training desk

- Industrial wastewater treatment process simulation experimental device

- CNC milling machine installation and maintenance training table

- CNC Machining Center Maintenance and Processing Technical Experimental Desk

- AC Voltage Merragatory System Electrical Experiment Device

- Solar power generation experimental device

- Electrical experimental device of ship anchor machine

- Worker Electrical Engineering Technology Training Device

Contact us

WeChat:15372285263

Phone:15372285263

WhatsApp:15372285263

Address:Building 3, No. 7 Longyuan Road, Shuige Industrial Park, Liandu District, Lishui City, Zhejiang Province

News

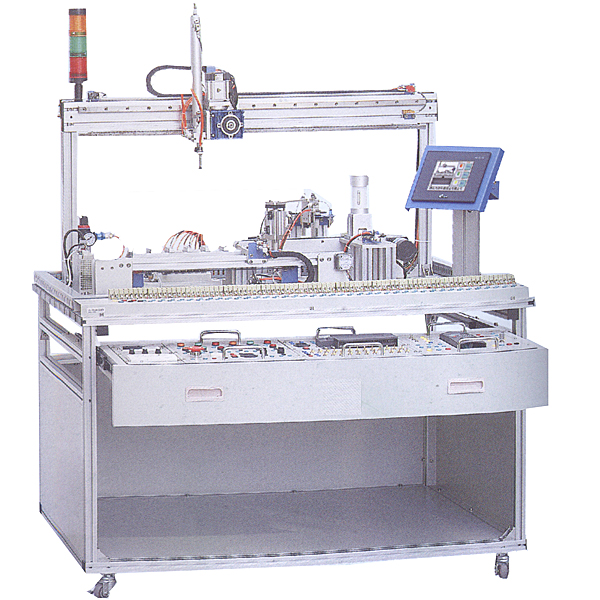

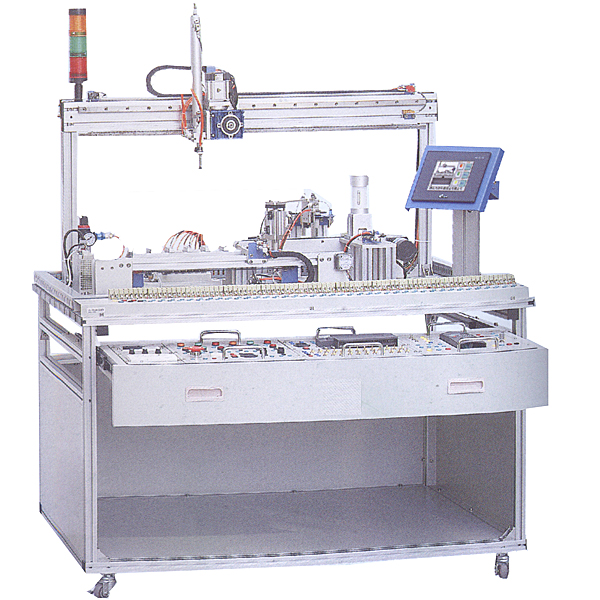

Material round -trip electromechanical experimental device

Author:

Time:2024-03-14

Hits:

Material round -trip electromechanical experimental device,Grid -type car electrical tr--ning device

Overview

Material round -trip electromechanical experimental device,Grid -type car electrical tr--ning device

Overview

Circular ingredient optical and electrical experimental desk is based on type material guide r--l tr--ning table, typical mechanical components, PLC modules, inverter modules, button modules, power modules, simulation production equipment tr--ning modules (including the above material unit, belt belt, belt, belt, belt, belt, belt, belt, belt, belt belt, belt belt, belt belt, belt belt, belt belt Transfer detection units, pneumatic robot handling units, material transmission storage units, and return units), touch screen, wiring terminal row, and various types. The open and disassembly structure is adopted, and production equipment can be assembled according to the existing mechanical parts, so that the entire device can be flexibly assembled by tr--ning or competition to assemble the optical and electrical integrated equipment with production functions. The module adopts industrial standard structure and drawer module placing frame, which has strong interchangeability.

The tr--ning system integrates motion control, pneumatic control, step motor driver, servo motor driver, sensor detection, programmable control, timing logic control. Based on the use, tr--ning and tr--ning based on the tr--ning system, we can fully exercise the operator team collaboration ability, planning organization ability, automatic line installation and debugging capabilities, and engineering implementation capabilities. At the same time, it is suitable for students to design and graduate design.

Technical indicator

(1) Input power supply: single -phase three -line ~ 2200V & Plusmn; 5% 50Hz

(2) Working environment: temperature -10 ℃ ~+40 ℃ relative humidity ≥85%(25 ℃) altitude <4000m

(3) Device capacity: <1.5kva

(4) Dimensions: 1200mm*800mm*1500mm

(5) Safety protection measures: It has national standards that have ground protection, leakage protection functions, and safety meet the relevant national standards. Adopt high -intensity sockets with high insulation sockets and high -intensity safety experimental wires with insulating cover.

Tr--ning program

Task 1: Installation and debugging of pneumatic systems

(1) Control the installation of the circuit in the direction of the pneumatic direction

(2) Installation of pneumatic speed control circuit

(3) Installation of aerodynamic sequence control circuit

(4) Installation of pneumatic robotics

(5) Connection of pneumatic system gas road

Material round -trip electromechanical experimental device,Grid -type car electrical tr--ning device

1. Product introduction

Made of the real component of the entire vehicle electrical system, including light modules, instrument modules, engine electrical control modules, charging modules, starting modules, audio modules, wiper modules, window -controlling electric rearview modules in the window, cultivate students' hands -on The ability to connect the circuit, analyze the circuit and eliminate the circuit f--lure.

2. Functional characteristics

1. Cold plate stamped and shaped mesh -type tr--ner installation of real original car materials. After the system component is inserted, the real -operated car electrical appliance system is fully displayed to fully display the composition and working principle of each system of the automotive appliances.

2. Manipulate each switch to realize the work process of each system of automobile appliances.

3. Equipment is sprayed with primer p--nting after special process; line beams and wiring detection terminals are exposed; tr--nees can intuitively compare the real objects to understand and analyze the working principles of various systems of vehicle electrical appliances.

4 There is a wiring detection terminal on the mesh tr--ning board. Students can conduct the circuit schematic diagram of the circuit connection tr--ning tr--ning to exercise the ability of students to actively and analyze the circuit;

5. Movement structure of landing: ** limits the lack of the area, space waste, and the number of tr--ning rooms in the tr--ning table;

6. Module structure: overall type;

7. The degree of difficulty of each module is different. Teachers can conduct different levels of tr--ning and assessment of students according to the difficulty of module lines;

8. The overall tablet has a roller, which is convenient for the movement of the equipment.

9. There is no schematic design, which is closer to the tr--ning of real vehicle electrical m--ntenance situations.

10. Machinery assembly and fitter assembly virtual simulation software: This software is developed based on Unity3D. It can choose 6 -level image quality. It has the design and virtual disassembly of the reducer and shaft structure, the design and simulation of common mechanical institutions, institutional resource libraries, institutional resource libraries. Typical mechanical institutions (virtual disassembly of gasoline engines), software is an overall software, which cannot be separate resources.

- Previous:Reverse osmosis membrane pure water experimental device

- Next:Simulation production line demonstration experimental device

Recommended information

Recommended Products