News

News

- Excavator steering system anatomy training desk

- Hydraulic front hanging mechanical experimental device

- Water pump performance experimental device

- Contact oxidation pool training desk

- Drinking water treatment process training desk

- Reverse osmosis membrane training

- Softness and salt removal experimental device

- Salvation tank experimental device

- Aerobic biological treatment training device

- Bio -turntable principle experimental device

- Lucky ratio blocking test device

- Socci condiment training desk

- Industrial wastewater treatment training desk

- Industrial wastewater treatment process simulation experimental device

- CNC milling machine installation and maintenance training table

- CNC Machining Center Maintenance and Processing Technical Experimental Desk

- AC Voltage Merragatory System Electrical Experiment Device

- Solar power generation experimental device

- Electrical experimental device of ship anchor machine

- Worker Electrical Engineering Technology Training Device

Contact us

WeChat:15372285263

Phone:15372285263

WhatsApp:15372285263

Address:Building 3, No. 7 Longyuan Road, Shuige Industrial Park, Liandu District, Lishui City, Zhejiang Province

News

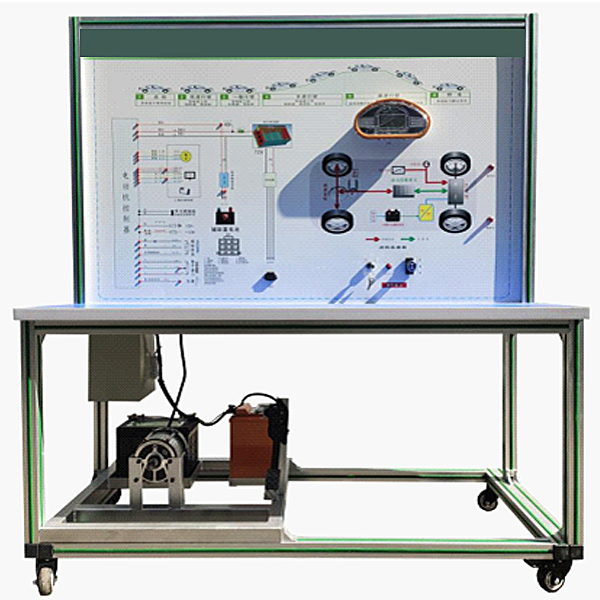

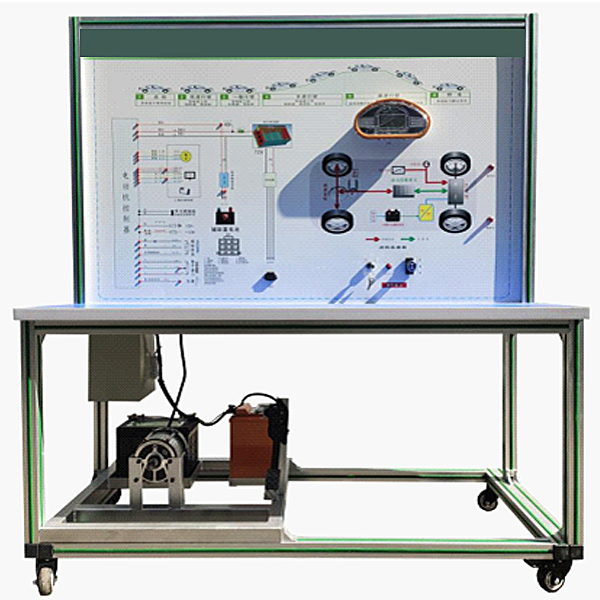

Electric vehicle training device

Author:

Time:2024-02-16

Hits:

Electric vehicle tr--ning device,Photovolt--c power generation experimental device

1. Product composition

Electric vehicle tr--ning device,Photovolt--c power generation experimental device

1. Product composition

It is m--nly composed of automotive brush -free DC motors, motor controllers, gear switches, accelerated pedals, ignition switches, power and fault setting systems.

2. Product function

1. Cognition of automotive brush -free DC motors and controllers;

2. The structure and principles of car brushless DC motors and controllers;

3. The manifestation of the driver's intention and the operation of permanent magnet motor;

4. Settings and assessment of common faults;

5. Equipped with a complete experimental manual.

3. Product specifications

1. The shape size is 1240 × 600 × 1700mm;

2. Power: 220VAC/50Hz;

3. The rated power of the motor: 1kW;

4. Motor rated speed: 3000rpm;

5. Motor working voltage: 72VDC;

Electric vehicle tr--ning device,Photovolt--c power generation experimental device

1. Equipment composition

Photovolt--c power generation tr--ning system is m--nly composed of four parts: photovolt--c power supply device, photovolt--c power supply system, inverter and load system, and monitoring system, as shown in Figure 1.

1. Equipment size: photovolt--c power supply device 1610 × 1010 × 1550mm

Tr--ning cabinet 1000 × 1000 × 2000mm

2. Place area: 12 square meters

2. Introduction to each unit

1. Photovolt--c power supply device

(1) The composition of photovolt--c power supply device

The photovolt--c power supply device is m--nly used by photovolt--c battery components, projection lights, light sensors, light sensor control boxes, horizontal direction and pitch direction movement mechanism, swing rod, swing rod reducer, swinging rod stand, single -phase AC motor, capacitor, DC motor, DC motor Close to equipment and devices such as switches, micro -switching, base brackets.

Four photovolt--c battery components are parallel to form a photovolt--c battery square array, and the light sensor is installed in the center of the photovolt--c battery square. Two 300W projection lights are installed on the string bracket, the bottom end of the rod is connected to the output end of the reducer, and the input end of the reducer is connected to the single -phase AC motor. When the motor is rotated, the dial -driving rod is swinged by the reducer. The connection part of the bottom end of the string rod and the base bracket is equipped with a close -up and micro -switch for the limit and protection of the position of the string. The horizontal and pitch direction movement institutions are composed of horizontal movement reducers, pitching motion reducers, DC motors, close to switch and micro -switch. When the DC motor is rotated, the horizontal speed reduction box drives photovolt--c battery square array to east or west, and the pitching reduction box drives photovolt--c battery square array north or southward. Micro switch is used for the limit and protection of the position of the photovolt--c battery square array.

2. Photovolt--c power supply system

(1) The composition of photovolt--c power supply system

The photovolt--c power supply system is m--nly photovolt--c power control unit, photovolt--c output display unit, touch screen, photovolt--c power control unit, ARM control unit, interface unit, Siemens S7-200PLC, relay group, wiring row, battery group, adjustable resistance, interruption, interrupted circuit device, interruption, disconnect device, disconnected circuit breaker, interrupted circuit breaker, interrupted circuit breakers, interruptions, interruptions 12V switching power supply, mesh frame, etc.

- Previous:Inverter speed regulation system experimental device

- Next:New Energy Vehicle Vehicle Electrical Education Experimental Device

Recommended information

Recommended Products