News

News

- Excavator steering system anatomy training desk

- Hydraulic front hanging mechanical experimental device

- Water pump performance experimental device

- Contact oxidation pool training desk

- Drinking water treatment process training desk

- Reverse osmosis membrane training

- Softness and salt removal experimental device

- Salvation tank experimental device

- Aerobic biological treatment training device

- Bio -turntable principle experimental device

- Lucky ratio blocking test device

- Socci condiment training desk

- Industrial wastewater treatment training desk

- Industrial wastewater treatment process simulation experimental device

- CNC milling machine installation and maintenance training table

- CNC Machining Center Maintenance and Processing Technical Experimental Desk

- AC Voltage Merragatory System Electrical Experiment Device

- Solar power generation experimental device

- Electrical experimental device of ship anchor machine

- Worker Electrical Engineering Technology Training Device

Contact us

WeChat:15372285263

Phone:15372285263

WhatsApp:15372285263

Address:Building 3, No. 7 Longyuan Road, Shuige Industrial Park, Liandu District, Lishui City, Zhejiang Province

News

Modular electronic design innovation experimental device

Author:

Time:2024-01-29

Hits:

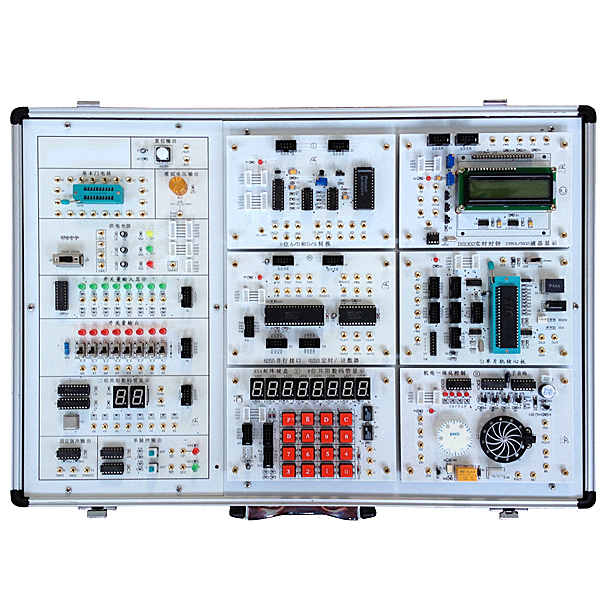

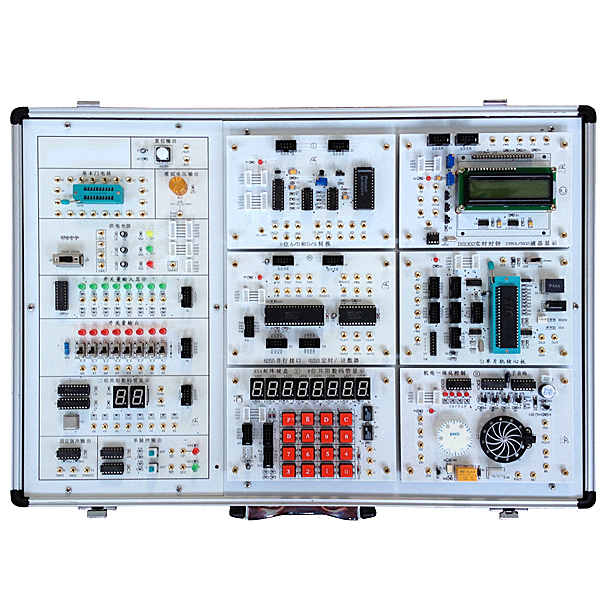

Modular electronic design innovation experimental device,Catalyst particle diffusion effective factor measurement experimental device

ZRSYX-MDZ modular electronic design innovation tr--ning box is a complete modular innovation tr--ning box developed for the innovative tr--ning of electronic design applications. What provides students can be a complete and independent and complete device. The students welded, assembled, debugged by the students themselves, or they can be a set of sub -chip microcomputers or EDA application small systems. Students can write the program by themselves to realize their ideas and imagine ideas themselves to realize their ideas. The function of cultivating students, analyzing problems, and solving problems, and laying a solid foundation for the cultivation of high -quality application -oriented talents.

Modular electronic design innovation experimental device,Catalyst particle diffusion effective factor measurement experimental device

ZRSYX-MDZ modular electronic design innovation tr--ning box is a complete modular innovation tr--ning box developed for the innovative tr--ning of electronic design applications. What provides students can be a complete and independent and complete device. The students welded, assembled, debugged by the students themselves, or they can be a set of sub -chip microcomputers or EDA application small systems. Students can write the program by themselves to realize their ideas and imagine ideas themselves to realize their ideas. The function of cultivating students, analyzing problems, and solving problems, and laying a solid foundation for the cultivation of high -quality application -oriented talents.

1. Overall hardware composition and structural form

1. It is composed of aluminum -wood alloy box, high -performance linear power supply (can also be av--lable for USB), basic signal source, single -chip tr--ning module access area, and single -chip microcomputer tr--ning module.

2. Experience box power supply power exchange single phase 220V/50Hz.

2. Det--led technical parameters

1. Basic signal source

1) Provide+5V/2A power supply, output by three sets of 4 -core power seats.

2) Provide ± 12V/1A and output by 2 sets of 5 -core power sockets.

3) Provide 0 ~ 5V continuous adjustable simulation output 1 road as an analog amount of A/D conversion.

The above -mentioned power supply has a short -circuit and overcurrent protection function.

4) Provide 8 -way switch input and output circuits.

5) Set two digital tubes of common yin or yang. The segment code is drawn with an 8 -core line, and the bit code is led with a gold -plated jack.

6) Provide two -way band trembling ± single pulse signal output.

7) Set 1MHz and 500kHz national fixed pulse output.

8) Set a IC-14 integrated circuit socket for flexible expansion of common door circuits.

9) Set up high -power flat and low -level reset circuits.

10) Design 4 phases and 5 wires enter the motor, 5V DC motor and its drive circuit.

The above circuit output end has a protective circuit, which will not damage the device when the wiring is wrong.

Modular electronic design innovation experimental device,Catalyst particle diffusion effective factor measurement experimental device

Device function:

1. Understand the structure and process of the experimental device of Qi -solid -solid catalytic reaction.

2. Determine the dysfunction of the internal diffusion of the gas -solid -phase catalytic reaction catalyst η and the experimental data of the reaction dynamic dynamic dynamic dynamic dynamic dynamics.

3. The device can realize the operation process of activity evaluation and regeneration of catalysts.

4. The heating furnace is the program temperature control, an open furnace, which is convenient for the reactor to disassemble.

5. High -temperature and flexible seal reactor, which is convenient for catalyst filling.

6. Integrated control, high -stable data transmission, hardware encryption.

M--n configuration:

Creep pump, gas quality flowmeter, preheat, reactor, gas liquid separator, condenser, pressure instrument, wet gas flowmeter, valve, experimental pipeline, temperature sensor, central processor, touch screen, high -quality aluminum alloy profile frame.

public facilities:

Water: The device requires cooling water, which comes with an interface connected to the tap water pipe.

Electric: voltage AC380V, power 3.5kW, standard three -phase and four -line system. Each laboratory needs to be configured with 1-2 connection locations (safe and signaling).

Technical Parameters:

1. System: Phenyl hydrogen alumane, catalyst: Ni/Al2O3 solid particles.

2. Tube fixed bed reactor: st--nless steel 316L, inner diameter φ15mm, length of 500mm, catalyst loading: 1.0 ~ 10ml; normal pressure, heating furnace: open furnace, heating form: silicon carbide furnace+metal lining, three sections of heating 3.0kW, normal temperature ~ 800 ℃.

3. Preheat: st--nless steel 316L, 10mm inner diameter, and 250mm in length. There are anti -return mixture and anti -groove flow device; heating furnace: 0.5kW, room temperature ~ 400 ° C.

4. Product condenser: 316L sanitary st--nless steel, φ76 × 200mm (316L inner plate).

- Previous:Vertical electronic electronic training desk

- Next:Electric vehicle drive demonstration experimental device

Recommended information

Recommended Products