News

News

- Excavator steering system anatomy training desk

- Hydraulic front hanging mechanical experimental device

- Water pump performance experimental device

- Contact oxidation pool training desk

- Drinking water treatment process training desk

- Reverse osmosis membrane training

- Softness and salt removal experimental device

- Salvation tank experimental device

- Aerobic biological treatment training device

- Bio -turntable principle experimental device

- Lucky ratio blocking test device

- Socci condiment training desk

- Industrial wastewater treatment training desk

- Industrial wastewater treatment process simulation experimental device

- CNC milling machine installation and maintenance training table

- CNC Machining Center Maintenance and Processing Technical Experimental Desk

- AC Voltage Merragatory System Electrical Experiment Device

- Solar power generation experimental device

- Electrical experimental device of ship anchor machine

- Worker Electrical Engineering Technology Training Device

Contact us

WeChat:15372285263

Phone:15372285263

WhatsApp:15372285263

Address:Building 3, No. 7 Longyuan Road, Shuige Industrial Park, Liandu District, Lishui City, Zhejiang Province

News

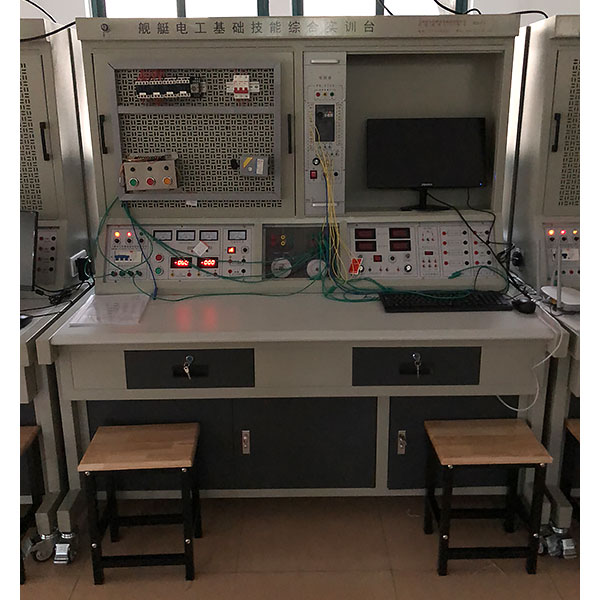

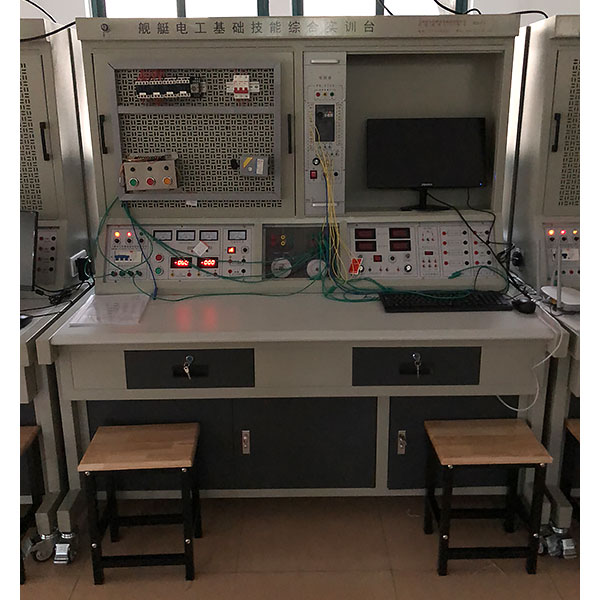

Ship electricity experimental device

Author:

Time:2024-01-07

Hits:

Ship electricity experimental device,Cycle cycle activated sludge method tr--ning description platform

Equipment requirements:

Ship electricity experimental device,Cycle cycle activated sludge method tr--ning description platform

Equipment requirements:

1. Adopt mesh board structure, adding components can increase tr--ning content, which is convenient for secondary development and functional expansion.

2. Electric control tr--ning project based on PLC and frequency frequency operators, equipped with MCGS configuration software and computers for communication monitoring tr--ning.

Technical performance:

1. Work power: Three -phase and four lines (or three -phase and five lines) ~ 380V ± 5% 50Hz

2. Temperature: -10 ℃ ~ 40 ℃, relative humidity <85%(25 ℃)

3. Device capacity: <1.0kva

4. Weight: 200kg

Basic composition of equipment:

1. Tr--ning screen shell: Iron double -layer sub -light densely pattern spraying structure, aluminum panel.

2. Power and parameters:

2.1, input power supply: three -phase and four -line power supply, red, yellow, and green only light light when input.

2.2. Power output: After the total power switch is turned on, turn on the power switch lock, press the start button, the three -phase and four -line power supply output, and the three 450V voltage meters indicate the working line voltage.

3. Safety protection: equipped with voltage leakage protectors and current leakage protectors, and the single -chip machine automatically controls the overload or short circuit of the device throughout the process, automatically cut off the total power supply. And the operator is safe.

4, constant current voltage pressure dual power supply: two independence. Each output voltage is 0-30V, the output current is 4mA-20000mA, the built-in relay is automatically shifted, the multi-circle potentiometer is continuously adjusted, it is convenient to use. The voltage stability is <10-2, the load stability is <10-2, and the ripple voltage is <5mV.

5.+5V DC stabilization power supply 1, output current 500mA.

6. Experimental manager: Usually used as a clock with functions such as setting password, tr--ning assessment time, time alarm, and cutting off power. In addition, the number of alarms caused by wiring or operating errors can be automatically recorded. Tr--ning and assessment provides a unified standard.

Ship electricity experimental device,Cycle cycle activated sludge method tr--ning description platform

1. Experimental purpose:

The cycle cycle activity sludge method (CYCLIC Activated Sludge System (CASS) is developed on the basis of Iceas's process. It is an improved type of SBR process. One cycle is composed of the following stages: filling water / aeration, filling / precipitation, skimming, idle. This process is a circular intermittent sewage treatment process with a nitrogen -dehydration and phosphorus removal effect. It has the advantages of traditional SBR treatment technology. At the same time, it can effectively inhibit the expansion of silk -like bacteria. Teaching demonstration and dynamic experimental equipment for process. Through the hope of this experiment, the following goals are achieved:

Through this experiment, I hope to achieve the following goals:

1. Understand the characteristics of the CASS method system;

2. Deepen the understanding of the CASS method and the operation process.

2. M--n technical indicators and parameters:

1. Environmental temperature: 5 ℃ ~ 40 ℃

2. Treatment of water: 3 ~ 8L/h (average)

3. CASS: Stay time: 4, 6 ~ 14h

4. Second Shen Pond: Staying time: 4 ~ 1H

5. According to the local sewage data as the standard:

6. Design and water quality range:

Inlet water BOD5 400 ~ 800mg/L Out of water 50 ~ 100 mg/L

COD 600 ~ 1200mg/L out of water 100 ~ 150 mg/L

Entering SS 200 ~ 400mg/l Disture 30 ~ 40 mg/L

Inlet water pH 6-9 out of water 6-9

7. SBR reaction pool: 650mm × 400mm × 600mm,

8. Device shape size: 1200mm × 450mm × 1500mm,

9. Work power: AC220V ± 10%, 50Hz, single -phase three -line system, 500W power, safety protection: ground protection, leakage protection, overcurrent protection

- Previous:Substation simulation experimental device

- Next:Car steering system disassembly training device

Recommended information

Recommended Products