News

News

- Excavator steering system anatomy training desk

- Hydraulic front hanging mechanical experimental device

- Water pump performance experimental device

- Contact oxidation pool training desk

- Drinking water treatment process training desk

- Reverse osmosis membrane training

- Softness and salt removal experimental device

- Salvation tank experimental device

- Aerobic biological treatment training device

- Bio -turntable principle experimental device

- Lucky ratio blocking test device

- Socci condiment training desk

- Industrial wastewater treatment training desk

- Industrial wastewater treatment process simulation experimental device

- CNC milling machine installation and maintenance training table

- CNC Machining Center Maintenance and Processing Technical Experimental Desk

- AC Voltage Merragatory System Electrical Experiment Device

- Solar power generation experimental device

- Electrical experimental device of ship anchor machine

- Worker Electrical Engineering Technology Training Device

Contact us

WeChat:15372285263

Phone:15372285263

WhatsApp:15372285263

Address:Building 3, No. 7 Longyuan Road, Shuige Industrial Park, Liandu District, Lishui City, Zhejiang Province

News

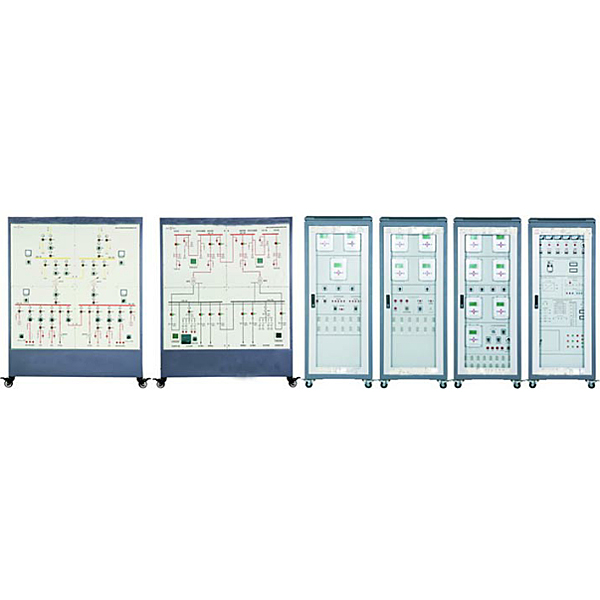

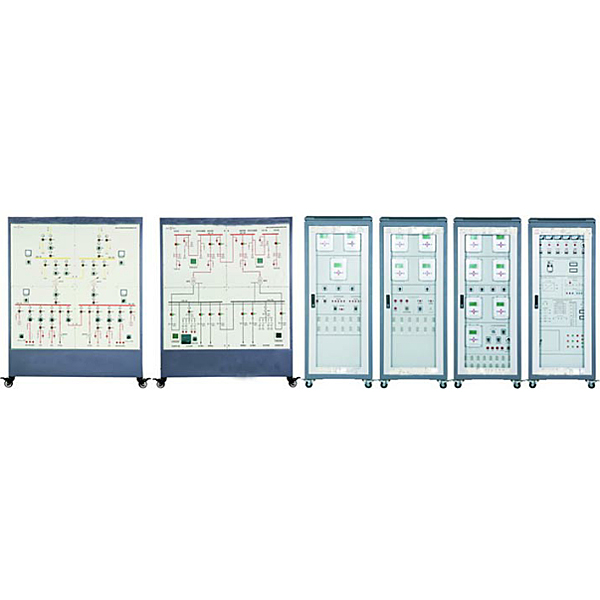

Substation simulation experimental device

Author:

Time:2024-01-07

Hits:

Substation simulation experimental device,UASB anaerobic fermentation column experimental device

I. Overview

Substation simulation experimental device,UASB anaerobic fermentation column experimental device

I. Overview

The system consists of three parts: a system screen, secondary protection cabinet, and a substation background system. At one time, the system uses a typical 110kV substation project as a model. There are two m--n variants, both of which are equipped with pressure -regulating types; two -way entry line, 110kV side and 10kV side use single -parent segments, 35kV side uses single -parent segment bands using single -parent segment bands The mother wiring. All the second parts use the micro -model relay protection device and measurement and control device, which are divided into four protective cabinet installations; the data can be uploaded, the monitoring host command can be accepted, and the requirements of the "Four Yao" function and remote mobility are fully met. At the same time, multi -serial cards are used to solve the problem of communication bottleneck between the protection device and the background system.

Two and characteristic

1. There is a typical complete system. The switch and knife gate use different types of switch operations, and the mutual lock settings are complete. Electrical circuits can be set up in various types;

2. The configuration of the secondary relay protection device is complete;

3. The interval layer has good performance, reliable running;

4. The communication system has an independent communication channel to meet the requirements of unmanned duty;

5. Good setability, complete configuration of primary, secondary systems, and monitoring systems;

6. Strong openness, the protection and control device adopts a standard communication protocol, and the software system adopts industrial configuration software to open protocols.

Third, tr--ning project

Line protection

(1) Normal, maximum, and minimum operation of the system

(2) Short -circuit of electrical systems

(3) Basic functional testing of microcomputer protection device

(4) Microcarmark time limit over current protection

(5) Microcarmarking current speed break protection protection

(6) The speed of the time limit of the microcomputer band

(7) Phase current protection

(8) The impact of the operation method on the protection of the protection and sensitivity verification

(9) current voltage ch--n protection

(10) Reverse time limit protection experiment

Substation simulation experimental device,UASB anaerobic fermentation column experimental device

1. Experimental purpose:

Aerobic biological treatment technology is not only used for organic sludge and high concentration organic wastewater, but also can treat low concentration sewage. Compared with aerobic biological treatment technology, anaerobic biological treatment has high organic load, low sludge yield, energy consumption, energy consumption A series of obvious advantages. The lift -type anaerobic sludge bed (UASB) is a major structure of anaerobic biological treatment. It integrates anaerobic biological reactions and sedimentation separation. Organic load and removal efficiency are high, and no mixing equipment is required. This model is a teaching experimental equipment for lift -type anaerobic sludge beds. Through the hope of this experiment, the following goals are achieved:

1. Understand the internal structure of UASB;

2. Master the launching method of UASB, the formation of granules sludge;

3. Dynamic tests on a cert--n sewage to determine process parameters and process water quality.

2. M--n technical indicators and parameters:

1 Environmental temperature: 5 ℃ ~ 40 ℃

2 Treatment of water: 2 ~ 5L/H

3. Design in and out of water quality range:

Inlet water BOD5 1000 ~ 2000mg/L Out of water 50 ~ 100 mg/L

COD 2000 ~ 4000mg/L out of water 150 ~ 300 mg/L

Enter the water 100 ~ 300mg/L out of water 20-50 mg/L

Inlet water pH 6-9 out of water 6-9

4. The outer diameter of the cylinder is φ150mm × 2000mm.

5. Device shape size: 1200mm × 400mm × 2300mm

6. Work power: AC220V ± 10%, 50Hz, single -phase three -line system, power 800W, safety protection: ground protection, leakage protection, overcurrent protection

3. M--n configuration:

1. 1 original water tank: white PP plate material, 10mm thickness, 300 × 300 × 400mm, empty valve installed on the bottom plate, which is convenient for cleaning the water;

2. 1 water tank: white PP plate material, 10mm thickness, 200 × 300 × 400mm, empty valve installed on the bottom plate, which is convenient for cleaning the water;

3. 1 set of paddles from the original water tank mixing motor, 304 st--nless steel mixing paddle; (power 25W, speed 120rpm), (including 1 tone speeder)

4. 1 set of UASB anaerobic reactor device, with a covering heating, 5 copper sampling ports, transparent organic glass material, wall thickness 7mm, ø150 × 2000mm, and one group of three -phase separators in the upper part. Valve, mud valve, water outlet valve, --r valve, etc. Attachment includes: 1 set of st--nless steel heating constant temperature water bath, 1 set of heating temperature water sets (generally m--nt--n 35-45 degrees), 1 circulating constant current water pump (maximum r--sing 10m, rated traffic 12L/min, power 90W), temperature control system 1 Set (temperature control accuracy: ± 1 ℃), 1 PT100 temperature sensor;

5. 1 water intake measurement peristaltic pump, flow range: 0.008-460ml/min,

6. 1 biogas flow meter

- Previous:Training device of biological turntable principles

- Next:Ship electricity experimental device

Recommended information

Recommended Products