Product

News

- Excavator steering system anatomy training desk

- Hydraulic front hanging mechanical experimental device

- Water pump performance experimental device

- Contact oxidation pool training desk

- Drinking water treatment process training desk

- Reverse osmosis membrane training

- Softness and salt removal experimental device

- Salvation tank experimental device

- Aerobic biological treatment training device

- Bio -turntable principle experimental device

- Lucky ratio blocking test device

- Socci condiment training desk

- Industrial wastewater treatment training desk

- Industrial wastewater treatment process simulation experimental device

- CNC milling machine installation and maintenance training table

- CNC Machining Center Maintenance and Processing Technical Experimental Desk

- AC Voltage Merragatory System Electrical Experiment Device

- Solar power generation experimental device

- Electrical experimental device of ship anchor machine

- Worker Electrical Engineering Technology Training Device

Contact us

WeChat:15372285263

Phone:15372285263

WhatsApp:15372285263

Address:Building 3, No. 7 Longyuan Road, Shuige Industrial Park, Liandu District, Lishui City, Zhejiang Province

Vehicle repair training

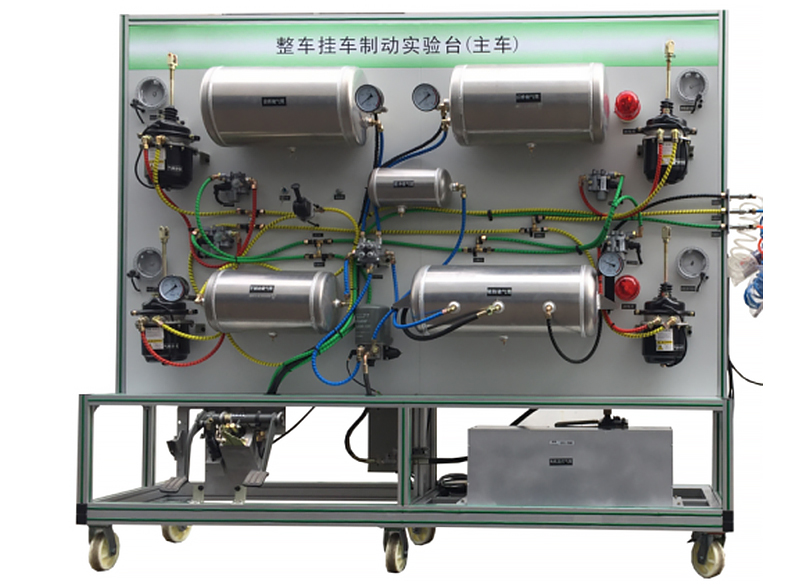

ZOPGC-07 gas pressure braking system training platform

The training platform of the gas pressure brake system, the new ZC30 loader original vehicle component of the air pressure brake system training device has air compressor assembly, air desiccant, front bridge storage cylinder, rear bridge storage cylinder, hand brake storage, hand brake storage, Pureain, regenerative storage cylinder, auxiliary storage cylinder, four -circuit protective valve, braking foot valve, parking valve, successor valve, braking pipeline, and air pressure gauge.

1. Functional features

1. The original parts of the new ZC30 loader on the bench include *r compressor assembly, *r desiccant, front axle *r reservoir, rear axle *r reservoir, hand brake *r reservoir, regeneration *r reservoir, Auxiliary *r reservoir, four-circuit protection valve, brake foot valve, parking valve, relay valve, brake pipeline, and several *r pressure gauges.

2. The non-original components on the bench include a two-phase AC drive motor , drive belt, and *r pressure gauge;

3. The layout of the components is generally close to the direction and position of the actual vehicle;

4. The compressor has an oil lubrication system;

5. The compressor *r is filtered by the *r filter;

6. Each component is placed in a reasonable and beautiful position, making it easy to see the appearance characteristics;

7. Different types of *r pressure pipelines are expressed in different colors (refer to the color of the actual vehicle pipelines) , the pipeline direction is simple and clear, making it easy to see the pipeline direction, and adopts a str*ght or str*ght-turn layout;

8. The bench has a teaching board to accurately draw its system composition and component connection diagram, and the color of the pipeline is consistent with the actual pipeline The color is consistent (the color after treatment);

the rotating parts of the driving motor are protected to prevent foreign objects from being squeezed by the belt;

10. The support stand uses 4 universal casters; the front two universal casters with locking function; the rear Two swivel casters; casters and stand.

11. Product technology: The equipment frame is constructed of two integrated all-aluminum alloy profiles, 40mm×40mm and 40mm×80mm, which are oil-resistant, corrosion-resistant and easy to clean. It is equipped with 4 swivel casters with self-locking devices for easy movement.

2. Technical specifications

Overall dimensions: 2080×650×1900mm (length×width×height)

External power supply: AC 220V±10% 50Hz

Working temperature: -40℃~+50℃

*r machine: 0.75KW

Barometer: 0~1000kPa

mobile Casters: 150*100mm

3. Basic configuration (per unit)

2. The non-original components on the bench include a two-phase AC drive motor , drive belt, and *r pressure gauge;

3. The layout of the components is generally close to the direction and position of the actual vehicle;

4. The compressor has an oil lubrication system;

5. The compressor *r is filtered by the *r filter;

6. Each component is placed in a reasonable and beautiful position, making it easy to see the appearance characteristics;

7. Different types of *r pressure pipelines are expressed in different colors (refer to the color of the actual vehicle pipelines) , the pipeline direction is simple and clear, making it easy to see the pipeline direction, and adopts a str*ght or str*ght-turn layout;

8. The bench has a teaching board to accurately draw its system composition and component connection diagram, and the color of the pipeline is consistent with the actual pipeline The color is consistent (the color after treatment);

the rotating parts of the driving motor are protected to prevent foreign objects from being squeezed by the belt;

10. The support stand uses 4 universal casters; the front two universal casters with locking function; the rear Two swivel casters; casters and stand.

11. Product technology: The equipment frame is constructed of two integrated all-aluminum alloy profiles, 40mm×40mm and 40mm×80mm, which are oil-resistant, corrosion-resistant and easy to clean. It is equipped with 4 swivel casters with self-locking devices for easy movement.

2. Technical specifications

Overall dimensions: 2080×650×1900mm (length×width×height)

External power supply: AC 220V±10% 50Hz

Working temperature: -40℃~+50℃

*r machine: 0.75KW

Barometer: 0~1000kPa

mobile Casters: 150*100mm

3. Basic configuration (per unit)

| serial number | Name | Specifications and models | unit | quantity |

| 1 | Front left and right brake assemblies | Original vehicle parts | set | 1 |

| 2 | Rear left and right brake assembly | Original vehicle parts | set | 1 |

| 3 | brake pedal | Original vehicle parts | set | 1 |

| 4 | Brake master cylinder and brake distribution pump | Original vehicle parts | set | 1 |

| 5 | *r compressor | 0.75KW | tower | 1 |

| 6 | gas tank | Original vehicle parts | indivual | 1 |

| 7 | barometer | 0~1000kPa | indivual | 5 |

| 8 | One-way valve | Original vehicle parts | indivual | 1 |

| 9 | Vent | Original vehicle parts | indivual | 1 |

| 10 | dr*n valve | Original vehicle parts | indivual | 1 |

| 11 | Mobile stand (with self-locking casters) | tower | 1 | |

| 12 | *r desiccant | Original vehicle parts | Only | 1 |

| 13 | Front axle *r reservoir | Original vehicle parts | Only | 1 |

| 14 | Rear axle *r reservoir | Original vehicle parts | Only | 1 |

| 15 | Hand brake *r reservoir | Original vehicle parts | Only | 1 |

| 16 | Auxiliary *r reservoir | Original vehicle parts | Only | 1 |

| 17 | Circuit protection valve | Original vehicle parts | set | 1 |

| 18 | brake lines | Original vehicle parts | set | 1 |

- Previous:ZOPGC-09 Loader All Electrical Training Platform

- Next:ZOPGC-13 loader automatic transmission disassembly training platform

Recommended Products