Product

News

- Excavator steering system anatomy training desk

- Hydraulic front hanging mechanical experimental device

- Water pump performance experimental device

- Contact oxidation pool training desk

- Drinking water treatment process training desk

- Reverse osmosis membrane training

- Softness and salt removal experimental device

- Salvation tank experimental device

- Aerobic biological treatment training device

- Bio -turntable principle experimental device

- Lucky ratio blocking test device

- Socci condiment training desk

- Industrial wastewater treatment training desk

- Industrial wastewater treatment process simulation experimental device

- CNC milling machine installation and maintenance training table

- CNC Machining Center Maintenance and Processing Technical Experimental Desk

- AC Voltage Merragatory System Electrical Experiment Device

- Solar power generation experimental device

- Electrical experimental device of ship anchor machine

- Worker Electrical Engineering Technology Training Device

Contact us

WeChat:15372285263

Phone:15372285263

WhatsApp:15372285263

Address:Building 3, No. 7 Longyuan Road, Shuige Industrial Park, Liandu District, Lishui City, Zhejiang Province

Vehicle repair training

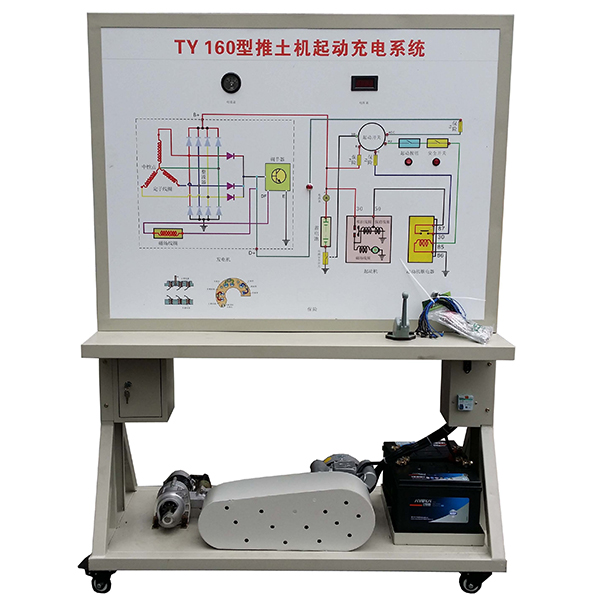

ZOPGC-04 Twita Twita Machine Starting and Charging System Training Platform

The bulldozer startup and charging system training desk, construction machinery startup and charging system training device uses TY160 bulldozer startup and charging system physical objects, fully display the structure and working process of starting and charging systems.

1. Product Introduction

The equipment is based on the actual starting and charging system of the TY160 bulldozer, fully demonstrating the composition and working process of the starting and charging system.

It is suitable for the teaching needs of schools on starting and charging system theory and m*ntenance tr*ning.

2. Functional features

1. Real and operational starting and charging system, fully demonstrating the composition and structure of the starting and charging system.

2. Manipulate the starting switch, start the starting motor and generator , and truly demonstrate the working process of the starting and charging system. The changing process of starting current and battery voltage during starting and charging can be observed through the ammeter and voltmeter on the panel.

3. The panel is made of 4mm thick high-grade aluminum-plastic panels that are corrosion-resistant, impact-resistant, pollution-resistant, fire-proof, and moisture-proof. The surface is sprayed with primer using a special process; the panel is printed with a color circuit diagram that will never fade; students can visually compare the circuit diagram and Real objects, understanding and analysis of the working principle of the starting system.

4. The panel is equipped with decomposed parts of the starter and generator assembly, allowing you to intuitively understand the composition of the starter and generator.

5. There are detection terminals installed on the panel, which can directly detect the electrical signals of various circuit components of the starting and charging system, such as resistance, voltage, current, frequency signals, etc.

6. The panel part adopts 1.5mm cold plate stamping structure, with beautiful appearance; the bottom part adopts steel structure welding, and the surface is spray-coated. It has a self-locking caster device. The base is equipped with a tabletop of about 40cm, which is convenient for placing materials and is lightweight. Testing instruments, etc.

7. Comprehensive integrated tr*ning virtual simulation system for professional skills:

based on unity3d design, users can choose different interactive interface sizes according to computer configuration, and six levels of image quality are optional. 4 types of cylindrical gear shafting components, 4 types of bevel gear shafting components, and 6 types of worm shafting components are av*lable for installation, disassembly, assembly, parts measurement (divided into shaft measurement and base measurement), assessment, etc. There are intelligent reminders during the steps of disassembly and assembly of parts. Students manually select the corresponding parts and move them to the shaft structure. Only by selecting the parts in the correct order can they be installed. The models in the software are all 3D models, produced by 3Dmax, and After rendering and polishing, the model looks the same as the real part. It has a non-standard parts library (8 types of parts), a standard parts library (12 types of parts), and a measurement tool library (steel ruler, vernier caliper) for disassembly and assembly. choose. The software is equipped with integrated electronic experiment assessment questions and instructions for the purpose, steps, and requirements of the experiment. When using the assessment function, questions are given for students to answer. When students finish answering the questions, assessment scores are given. There are 12 questions in total. Each question is set to 8 points (one of the questions is a multiple-choice question, accounting for 12 points). Only the selected The answer leads to the next question. The software needs to be able to rotate, zoom in, and zoom out in all directions to view its det*ls. The software must be on the same platform as a whole and must not be displayed as separate resources.

3. Technical specifications

Overall dimensions (approx.): 1240×600×1700mm (length×width×height)

External power supply: AC 220V±10% 50Hz

Working voltage: DC 24V

Working temperature: -40℃~+50℃

Color: 7032

steel pipe : 40*40*3mm

Cabinet: 1.5mm cold plate stamping, with m*ntenance door on the back;

Mobile casters: 100*60mm

4. Basic configuration (each unit)

The equipment is based on the actual starting and charging system of the TY160 bulldozer, fully demonstrating the composition and working process of the starting and charging system.

It is suitable for the teaching needs of schools on starting and charging system theory and m*ntenance tr*ning.

2. Functional features

1. Real and operational starting and charging system, fully demonstrating the composition and structure of the starting and charging system.

2. Manipulate the starting switch, start the starting motor and generator , and truly demonstrate the working process of the starting and charging system. The changing process of starting current and battery voltage during starting and charging can be observed through the ammeter and voltmeter on the panel.

3. The panel is made of 4mm thick high-grade aluminum-plastic panels that are corrosion-resistant, impact-resistant, pollution-resistant, fire-proof, and moisture-proof. The surface is sprayed with primer using a special process; the panel is printed with a color circuit diagram that will never fade; students can visually compare the circuit diagram and Real objects, understanding and analysis of the working principle of the starting system.

4. The panel is equipped with decomposed parts of the starter and generator assembly, allowing you to intuitively understand the composition of the starter and generator.

5. There are detection terminals installed on the panel, which can directly detect the electrical signals of various circuit components of the starting and charging system, such as resistance, voltage, current, frequency signals, etc.

6. The panel part adopts 1.5mm cold plate stamping structure, with beautiful appearance; the bottom part adopts steel structure welding, and the surface is spray-coated. It has a self-locking caster device. The base is equipped with a tabletop of about 40cm, which is convenient for placing materials and is lightweight. Testing instruments, etc.

7. Comprehensive integrated tr*ning virtual simulation system for professional skills:

based on unity3d design, users can choose different interactive interface sizes according to computer configuration, and six levels of image quality are optional. 4 types of cylindrical gear shafting components, 4 types of bevel gear shafting components, and 6 types of worm shafting components are av*lable for installation, disassembly, assembly, parts measurement (divided into shaft measurement and base measurement), assessment, etc. There are intelligent reminders during the steps of disassembly and assembly of parts. Students manually select the corresponding parts and move them to the shaft structure. Only by selecting the parts in the correct order can they be installed. The models in the software are all 3D models, produced by 3Dmax, and After rendering and polishing, the model looks the same as the real part. It has a non-standard parts library (8 types of parts), a standard parts library (12 types of parts), and a measurement tool library (steel ruler, vernier caliper) for disassembly and assembly. choose. The software is equipped with integrated electronic experiment assessment questions and instructions for the purpose, steps, and requirements of the experiment. When using the assessment function, questions are given for students to answer. When students finish answering the questions, assessment scores are given. There are 12 questions in total. Each question is set to 8 points (one of the questions is a multiple-choice question, accounting for 12 points). Only the selected The answer leads to the next question. The software needs to be able to rotate, zoom in, and zoom out in all directions to view its det*ls. The software must be on the same platform as a whole and must not be displayed as separate resources.

3. Technical specifications

Overall dimensions (approx.): 1240×600×1700mm (length×width×height)

External power supply: AC 220V±10% 50Hz

Working voltage: DC 24V

Working temperature: -40℃~+50℃

Color: 7032

steel pipe : 40*40*3mm

Cabinet: 1.5mm cold plate stamping, with m*ntenance door on the back;

Mobile casters: 100*60mm

4. Basic configuration (each unit)

| serial number | Name | Specifications and models | unit | quantity |

| 1 | Test control panel |

Equipped with various detection terminals, color circuit diagram and working principle diagram (panel: 1200*900*4mm) |

set | 1 |

| 2 | Ignition Switch | brand new | indivual | 1 |

| 3 | Starter assembly | brand new | Only | 1 |

| 3 | dynamo | brand new | Only | 1 |

| 4 | Starter assembly disassembled parts | set | 1 | |

| 5 | Generator assembly disassembled parts | set | 1 | |

| 6 | starter relay | indivual | 1 | |

| 7 | Voltmeter | 0~30V | indivual | 1 |

| 8 | Ammeter | 0~500A | indivual | 1 |

| 9 | battery | 46B24SR, 12V 45Ah, 550CCA | tower | 2 |

| 10 | m*n power switch | 50A | indivual | 1 |

| 11 | Mobile stand (with self-locking casters) | 1240×650×1700mm (length×width×height) | tower | 1 |

| 12 | Fault simulation and troubleshooting device | set | 1 | |

| 13 | charging indicator | indivual | 1 | |

| 14 | Three-phase asynchronous motor | YT100L1-4 | tower |

1 |

- Previous:ZOPNJ-40 harvesting machine full vehicle electrical appliance training and training platform

- Next:ZOPGC-03 Rubber crawler chassis training device

Recommended Products