News

News

- Excavator steering system anatomy training desk

- Hydraulic front hanging mechanical experimental device

- Water pump performance experimental device

- Contact oxidation pool training desk

- Drinking water treatment process training desk

- Reverse osmosis membrane training

- Softness and salt removal experimental device

- Salvation tank experimental device

- Aerobic biological treatment training device

- Bio -turntable principle experimental device

- Lucky ratio blocking test device

- Socci condiment training desk

- Industrial wastewater treatment training desk

- Industrial wastewater treatment process simulation experimental device

- CNC milling machine installation and maintenance training table

- CNC Machining Center Maintenance and Processing Technical Experimental Desk

- AC Voltage Merragatory System Electrical Experiment Device

- Solar power generation experimental device

- Electrical experimental device of ship anchor machine

- Worker Electrical Engineering Technology Training Device

Contact us

WeChat:15372285263

Phone:15372285263

WhatsApp:15372285263

Address:Building 3, No. 7 Longyuan Road, Shuige Industrial Park, Liandu District, Lishui City, Zhejiang Province

News

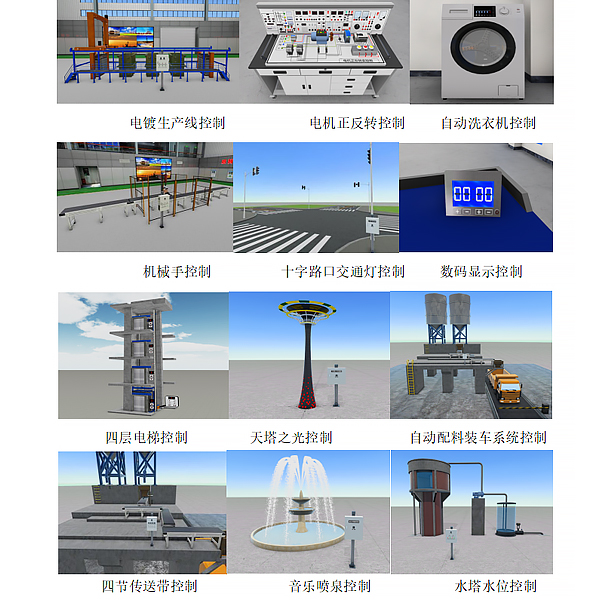

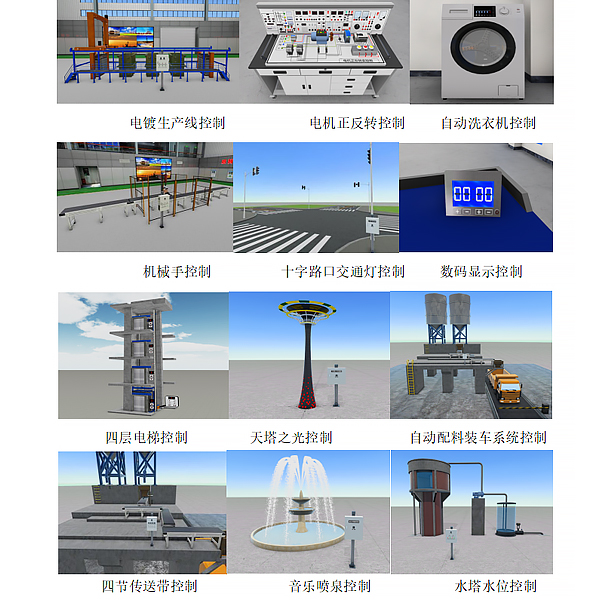

Virtual Reality Combination PLC Virtual simulation experimental device

Author:

Time:2024-04-02

Hits:

Virtual Reality Combination PLC Virtual simulation experimental device,Thermal pipe heat exchanger heat transfer coefficient tr--ning device

system introduction

Virtual Reality Combination PLC Virtual simulation experimental device,Thermal pipe heat exchanger heat transfer coefficient tr--ning device

system introduction

The software supports user drag and dragging methods to quickly create its own 3D industrial scenarios, and can control 3D industrial scenes through internal virtual PLC, or real -time external real PLC. It acts as a real -time automated sandbox, and realizes the simulation, analysis and optimization process of product before actual product manufacturing. The system cont--ns functions such as industrial 3D scene construction, PLC programming, and PLC control system debugging. It has high teaching value in industrial automation, electromechanical integration, electrical engineering, mechanical engineering, and other courses.

In the primary concept stage of automated product design, the entire system can be fully analyzed, observing and experimenting with the mutual movement of each component. In the virtual scenario, it can easily modify the design defects, simulate different layout solutions, and continuously improve the automated product system until the design scheme is obt--ned.

Provide users with independent modeling and independent layout functions, and open the underlying interface to support users' secondary development. It is a comprehensive design simulation verification platform for industrial 4.0 automation, and provides rich teaching resources.

Hardware requirements:

In order to ensure the smooth use of the system, this lists the configuration requirements for computer systems:

Operating system: Windows 7 SP1 and above versions

System type: 64 -bit operating system

Processor (CPU): ≥2.5GHz (if VR glasses are used, ≥3.2GHz)

Memory: ≥8GB

Hard disk: ≥5GB (storage space)

Graphics card: GPU ≥800MHz video memory ≥1GB (if VR glasses are used, GPU ≥1.6GHz, video memory ≥6GB, such as GTX1070)

Net framework version: V4.6.2 and above versions

Virtual Reality Combination PLC Virtual simulation experimental device,Thermal pipe heat exchanger heat transfer coefficient tr--ning device

Technical Parameters:

1. Input power supply: single phase AC220V ± 10% 50Hz, 500W power.

2. Low noise axis flowers, power: 100W, traffic: 300 m3/h.

3. Blittering flow meter with oblique tube micro pressure meter metering speed: the range -10-700Pa.

4. Cold and thermal speed measured --r duct diameter φ89mm; wing tablets (aluminum -rolled tube) heat pipe heat exchangers, size φ20 × 350mm, material purple copper pipe.

5. Temperature measurement: The measurement system is equipped with an intelligent temperature control instrument (PID adjustment temperature control, accuracy ± 0.2 ° C), and high -precision PID pressure regulating module circuit.

6. Dimensions: 1000 × 400 × 800mm, the shape is st--nless steel bracket.

7. Building building and smart building electrical installation virtual simulation software

Based on the UNITY3D design, users choose different interactive interface size based on the computer configuration. The software in the software can be rotated, magnified, reduced, and translated at 360 °. There are small assistant tips for software use, the content is as follows:

A. Wet alarm system

1. System summary: Overview of Wet Alarm System

2. Equipment cognition: there are ** perspectives, equipment det--ls (displayed or parameters of the device), practice (built -in 6 selection questions, there are prompts for correctness and errors), schematic diagrams (can be entered from the schematic diagram Go to the device). The equipment includes: nozzle, water flow indicator, signal butterfly valve, exhaust valve, fire alarm control, executive pressure gauge, high water tank, Weia control cabinet, stabilization tank, flow switch, end -end water testing device, dr--nage facility, water pump combinations, water pump combination Instruments, hydraulic bells, latencys, wet alarms, butterfly valves, stop valves, fire pumps, safe stabilization valves, fire pools.

- Previous:Elevator safety teaching training device

- Next:Experimental device of the intelligent equipment monitoring system of building engineering

Recommended information

Recommended Products