News

News

- Excavator steering system anatomy training desk

- Hydraulic front hanging mechanical experimental device

- Water pump performance experimental device

- Contact oxidation pool training desk

- Drinking water treatment process training desk

- Reverse osmosis membrane training

- Softness and salt removal experimental device

- Salvation tank experimental device

- Aerobic biological treatment training device

- Bio -turntable principle experimental device

- Lucky ratio blocking test device

- Socci condiment training desk

- Industrial wastewater treatment training desk

- Industrial wastewater treatment process simulation experimental device

- CNC milling machine installation and maintenance training table

- CNC Machining Center Maintenance and Processing Technical Experimental Desk

- AC Voltage Merragatory System Electrical Experiment Device

- Solar power generation experimental device

- Electrical experimental device of ship anchor machine

- Worker Electrical Engineering Technology Training Device

Contact us

WeChat:15372285263

Phone:15372285263

WhatsApp:15372285263

Address:Building 3, No. 7 Longyuan Road, Shuige Industrial Park, Liandu District, Lishui City, Zhejiang Province

News

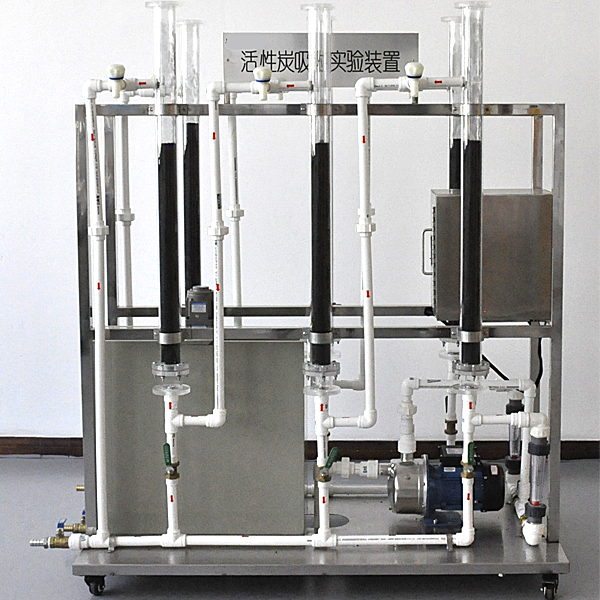

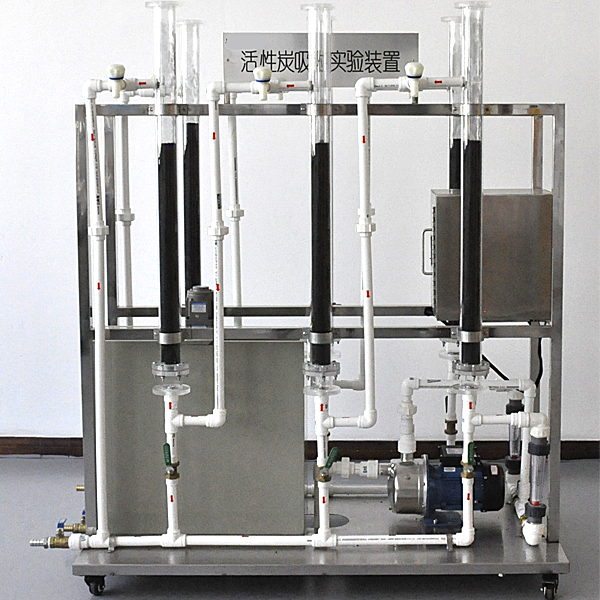

Activated carbon adsorption experimental device

Author:

Time:2024-03-02

Hits:

Activated carbon adsorption experimental device,Multaxim CNC processing center virtual reality tr--ning experimental device

1. Experimental purpose:

Activated carbon adsorption experimental device,Multaxim CNC processing center virtual reality tr--ning experimental device

1. Experimental purpose:

The activated carbon treatment process is an organic pollutant that uses adsorption to remove odor, cert--n ions, and difficulty in biodegradation. During the adsorption process, activated carbon plays a m--n role. At the same time, the solubility of the adsorption substance in the solvent also directly affects the speed of adsorption. In addition, the level of pH, changes in temperature, and decentralization of adsorption substances have a cert--n impact on adsorption speed.

This experiment adopts the method of intermittent and continuous adsorption of activated carbon, which determines the adsorption capacity of some impurities cont--ned in water through this experiment. Hope to achieve the following goals:

1. Master the basic operation process of adsorption experiments;

2. Deepen the basic principles of adsorption;

3. Master the physical significance and functions of adsorbing the temperature line;

4. Master the data processing method of activated carbon adsorption experiments;

5. Understand the adsorption performance of different activated carbon and its choice method.

2. M--n technical indicators and parameters:

1. Environmental temperature: 5 ℃ ~ 40 ℃

2. Active carbon suction column: φ100mm × 2000mm (group 2),

3. Device shape size: 1000mm × 600mm × 2200mm

4. Work power: AC220V ± 10%, 50Hz, single -phase three -line system, 200W power, safety protection: have ground protection, leakage protection, overcurrent protection, protection,

3. M--n configuration:

1. 2 active carbon suction columns (parallel): transparent organic glass material, 6mm wall thickness, φ100mm × 2000mm; water inlet pipes, dr--nage pipes, backwashing into the water pipe, rinse water pipe, empty exhaust pipe, sampling port, etc. Items

2. 1 raw water tank (white 10mm thick PP board), and the empty valve is installed on the bottom plate for convenience to clean the water;

3. Stir with a water tank motor of the original water tank, a set of 304 st--nless steel stirring paddles; (power 15W, speed 120rpm),

4. 1 setting pump for anticorrosive magnetic pumps, traffic: 27 ~ 32 (L/min), r--sing: 3.1 ~ 4.3 (m),

5. Two water flow flowmeters and backwashing flowmeters (10-100L/h),

6. 10 copper sampling ports; specifications ø10mm

Activated carbon adsorption experimental device,Multaxim CNC processing center virtual reality tr--ning experimental device

1. Product introduction

Intelligent manufacturing is the m--n direction of building a strong country. CNC machine tools are an important part of intelligent manufacturing. In response to the national call, the company introduced the world's advanced CNC software technology to develop this series of CNC machine tools virtual and real tr--ning machines. The tr--ning machine is combined by software and hardware. The functional is advanced, the quality is reliable, and the CNC system can be diversified.

At present, this type of products include: FANUC 0I-TF Plus (turning version), FANUC 0I-MF Plus (three-axis milling); Mitsubishi series Mitsubishi M80 (three-axis milling version); Siemens series Sinumeik 828D (turning version ), (Three -axis milling version), Sinumerik 840d (five -axis milling version); Hydehan series (five -axis milling version).

2. Product characteristics

The five -axis and five linkage CNC processing center is currently a CNC machine tool with high -end and complex processing procedures on the market. Programmers and operators also require very professional personnel to be competent. It is a high -precision CNC machine tool, which causes the school to be unable to purchase a large number of purchases and cause students to be unable to tr--n normally.

At present, professional teachers can only expl--n in the classroom through textbooks. Students do not have the cognition and experience of real machine tools during their learning. If they directly take students to real machine tool tr--ning, students will cause great psychological pressure. The actual factors such as the loss of the collision, the material and the tool, the machine tools are prone to damage, the unsafe, and the high teaching cost.

In order to solve the above factors, our company has developed a multi -purpose five -axis CNC machining center of the ** generation of one -generation machine. The device is combined by software and hardware. It has the functions of programming, processing, and debugging. The simulation operation of the five -axis CNC processing center of the shaft can be manually programmed or entered the CAD/CAM program for simulation processing. Highly simulating software CNC system interface is the same as the real CNC system. It is equipped with a real operating panel and hand wheel, so that students can experience the consistent operation experience of the real CNC machine tools during the learning process. Special design. The m--n body hardware of the device consists of four parts.

- Previous:Ozone decolorization experimental device

- Next:Microfiltration-ultrafiltration experimental device

Recommended information

Recommended Products