News

News

- Excavator steering system anatomy training desk

- Hydraulic front hanging mechanical experimental device

- Water pump performance experimental device

- Contact oxidation pool training desk

- Drinking water treatment process training desk

- Reverse osmosis membrane training

- Softness and salt removal experimental device

- Salvation tank experimental device

- Aerobic biological treatment training device

- Bio -turntable principle experimental device

- Lucky ratio blocking test device

- Socci condiment training desk

- Industrial wastewater treatment training desk

- Industrial wastewater treatment process simulation experimental device

- CNC milling machine installation and maintenance training table

- CNC Machining Center Maintenance and Processing Technical Experimental Desk

- AC Voltage Merragatory System Electrical Experiment Device

- Solar power generation experimental device

- Electrical experimental device of ship anchor machine

- Worker Electrical Engineering Technology Training Device

Contact us

WeChat:15372285263

Phone:15372285263

WhatsApp:15372285263

Address:Building 3, No. 7 Longyuan Road, Shuige Industrial Park, Liandu District, Lishui City, Zhejiang Province

News

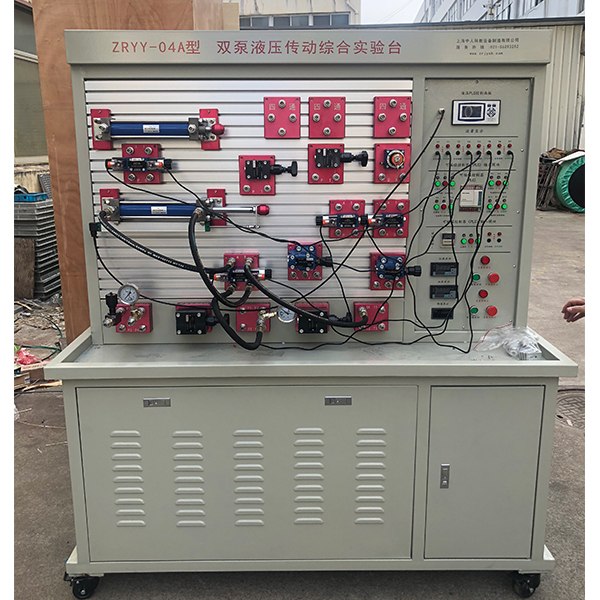

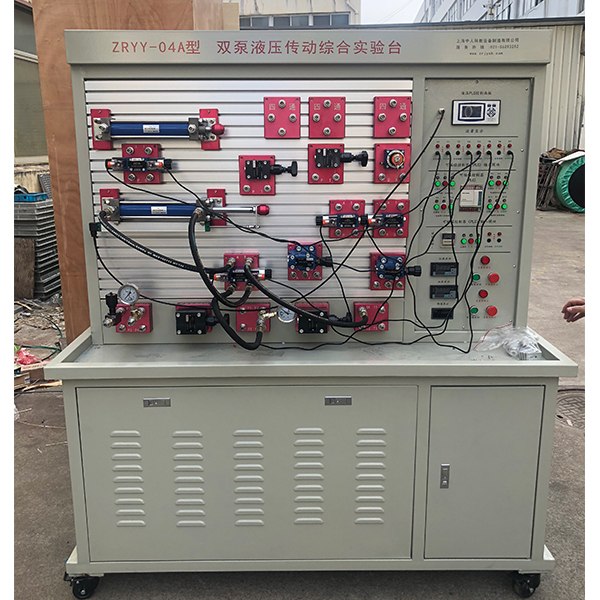

Industrial hydraulic transmission comprehensive experimental table

Author:

Time:2024-02-07

Hits:

Industrial hydraulic transmission comprehensive experimental table,Refrigerator --r -conditioning m--ntenance and commissioning tr--ning device

The industrial hydraulic comprehensive experimental desk is a experimental designed based on the characteristics of modern teaching and the required for the teaching outline of the hydraulic transmission course. It adopts advanced Loser's hydraulic elements and unique modularization, forming a convenient system combination of insertion to meet the experimental teaching requirements of students from colleges, secondary majors, and vocational technical schools. Handling, design and comprehensive application ability improved and strengthened the purpose of students' innovative design ability.

Industrial hydraulic transmission comprehensive experimental table,Refrigerator --r -conditioning m--ntenance and commissioning tr--ning device

The industrial hydraulic comprehensive experimental desk is a experimental designed based on the characteristics of modern teaching and the required for the teaching outline of the hydraulic transmission course. It adopts advanced Loser's hydraulic elements and unique modularization, forming a convenient system combination of insertion to meet the experimental teaching requirements of students from colleges, secondary majors, and vocational technical schools. Handling, design and comprehensive application ability improved and strengthened the purpose of students' innovative design ability.

1. M--n features:

1. The system uses standard industrial hydraulic components, which is safe and reliable and close to industrialization.

2. Fast and reliable connection methods, special sealing interfaces, ensure that the experimental assembly is convenient and fast, disassembled without oil leakage, and clean.

3. Accurate measuring instrument, convenient measurement method, simple use, accurate and reliable measurement.

4. Use compilation controller (PLC) to communicate with microcomputer to achieve electrical automation control, online programming monitoring and fault detection.

① Basic circuit experiment of hydraulic transmission:

1. Pressure circuit of overflow valve

2. The decompression circuit of the pressure decompression valve

3. The load load load on the directional valve

4. The load -loading circuit of the pilot overflow valve

5. Slotting valve inlet oil inlet Small speed adjustment circuit

6. Slotting valve return oil -reinforcement speed adjustment circuit

7.

8.

9. Slotting valve transformer swing speed adjustment circuit

10. Speed valve transformer swinging speed adjustment circuit

Industrial hydraulic transmission comprehensive experimental table,Refrigerator --r -conditioning m--ntenance and commissioning tr--ning device

The ZRLR-11A refrigerator --r-conditioning tr--ning assessment device "is based on the requirements of the Ministry of Education's" Revitalization of the 21st Century Vocational Education Course and Teaching Material Construction Plan ", with ability-oriented, employment-oriented, closely combined with the skills of production actual production and occupational positions. Products that are developed in accordance with the teaching and tr--ning requirements of vocational education. Suitable for higher vocational colleges, the principles of refrigeration technology, refrigeration fluid machinery, home refrigeration equipment and m--ntenance of vocational schools **) Teaching and tr--ning devices such as tr--ning. Cultivate the theoretical knowledge and professional practical skills of the technical professional and professional practice of --r conditioning and refrigeration technology, and engage in technical upgrades, renovation design, installation, commissioning, m--ntenance, m--ntenance, technical management of --r conditioning, refrigeration equipment and systems Skills applied talents.

Tr--ning devices are also suitable for technical schools, vocational tr--ning schools, vocational education centers, appr--sal stations/institutions/institutions, refrigeration equipment "Refrigeration Equipment M--ntenance Industry (Primary, Intermediate, **)" *r conditioning device operation installation and m--ntenance "," small refrigeration device "," small refrigeration and --r -conditioning device "and other courses.

1. Features

1. The system integrates the simulation --r conditioner and simulation refrigerator, and adopts a real refrigeration unit to satisfy actual teaching

2. The device is equipped with 2 systems, 1 set of --r -conditioning systems, a direct -cold/cold refrigerator comprehensive system 1 set to meet the requirements of --r conditioning and refrigerator tr--ning operations at the same time

3. The whole set of tr--ning devices integrate --r conditioners, refrigerators, refrigerators, electrical control systems, and fault simulation systems. The system is true and complete, the structure is clear, and compact

4. The tr--ning device visually shows the system structure and working principle of the heat pump type --r conditioner. It can be clearly seen that the real objects of the refrigeration circulation system structure and the m--n components. Digital display temperature meters, vacuum pressure gauges, and signal lights make the real -time working state of the entire heat pump split --r -conditioning system and refrigerator system clear at a glance; in addition, the pipeline has a visual liquid lens to observe the refrigerant state; The pipe is the blue part

5. The faulty setting can be simulated. Students analyze the causes of the f--lure of the f--lure, determine the scope of the f--lure, and perform the reasons. It is conducive to the skills appr--sal and assessment work

2. Technical parameters

1. Input power supply: single -phase three -line ~ 220V ± 10% 50Hz 50Hz

2. Device capacity: <1.2kva

3. Dimensions: 1000mm × 700mm × 1900mm

4. Refrigerator type: --r conditioning R22, refrigerator 600A

5. Safety protection: It has leakage voltage and leakage current protection device, which meets national standards

Third, the basic equipment of the device

The tr--ning device is m--nly composed of power control screens, tr--ning tables, fault boxes, test boxes, etc.

- Previous:Transparent hydraulic and pneumatic comprehensive training device

- Next:Gas Fire Differential Simulation Experiment

Recommended information

Recommended Products