News

News

- Excavator steering system anatomy training desk

- Hydraulic front hanging mechanical experimental device

- Water pump performance experimental device

- Contact oxidation pool training desk

- Drinking water treatment process training desk

- Reverse osmosis membrane training

- Softness and salt removal experimental device

- Salvation tank experimental device

- Aerobic biological treatment training device

- Bio -turntable principle experimental device

- Lucky ratio blocking test device

- Socci condiment training desk

- Industrial wastewater treatment training desk

- Industrial wastewater treatment process simulation experimental device

- CNC milling machine installation and maintenance training table

- CNC Machining Center Maintenance and Processing Technical Experimental Desk

- AC Voltage Merragatory System Electrical Experiment Device

- Solar power generation experimental device

- Electrical experimental device of ship anchor machine

- Worker Electrical Engineering Technology Training Device

Contact us

WeChat:15372285263

Phone:15372285263

WhatsApp:15372285263

Address:Building 3, No. 7 Longyuan Road, Shuige Industrial Park, Liandu District, Lishui City, Zhejiang Province

News

Electronic product design and production training device

Author:

Time:2024-01-23

Hits:

Electronic product design and production tr--ning device,Elevator well track facilities installation and debug tr--ning device

1. Equipment overview

Electronic product design and production tr--ning device,Elevator well track facilities installation and debug tr--ning device

1. Equipment overview

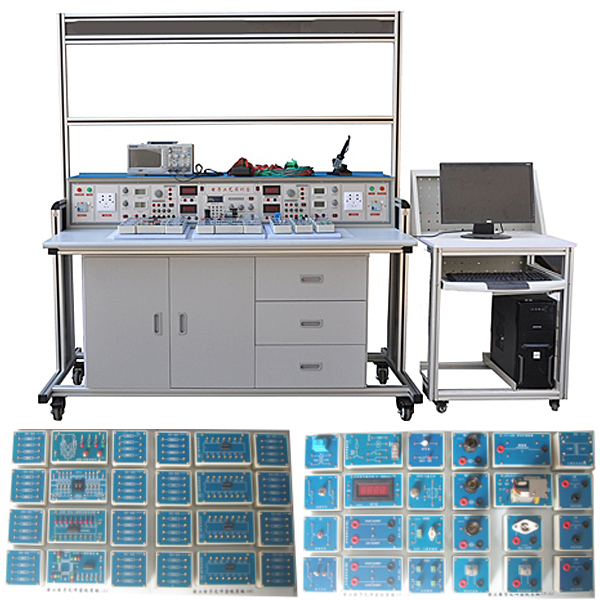

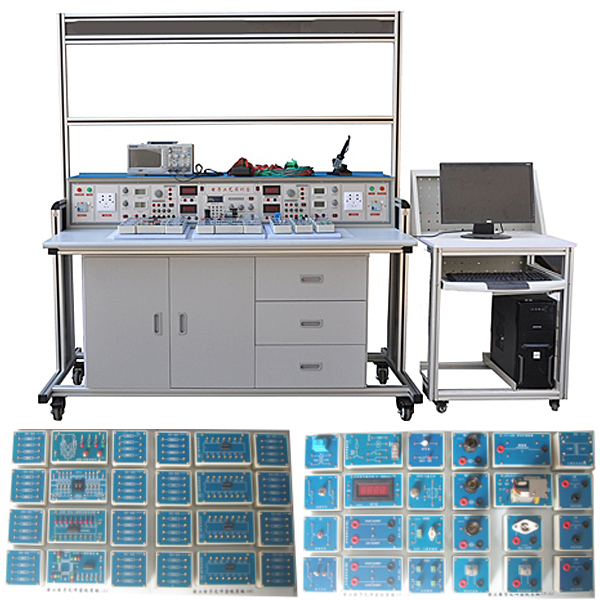

This experimental desk is suitable for experiments and tr--ning requirements for higher vocational colleges and ** technicians. Applicable majors include electronics, electronics, machinery, mechanical and electrical, and general engineering. <Electrical Engineering>, <Electrical Electronic Technology> and other courses and non -electrical majors in "Electrician and Electronic Technology" simulation and digital circuit module mathematics and experimental tr--ning can also meet electronic tr--ning; electronic component identification and test Circuit board welding, electronic product assembly, electronic product debugging, PCB board design and other tr--ning programs.

Electronic and electronic innovation tr--ning modules are composed of organic plastic boxes and PCB boards, including multiple combined modules, providing students with a platform for comprehensive application and innovative tr--ning to give full play to the full opening of students' potential.

2. Equipment technical indicators

(1) Work power: two -phase and three -line AC 220V ± 10% 50Hz 50Hz

(2) Temperature: -10 ~ 40 ℃; environmental humidity: ≤90%(25 ° C)

(3) Dimensions: length × width × height = 1600 × 850 × 1920mm

(3) The power consumption of the whole machine: ≤700V.A

(5) Safety protection measures: It has the function of ground protection, leakage protection, and safety standards that meet the relevant national standards. Adopt high -intensity sockets with high insulation sockets and high -intensity safety experimental wires with insulating cover.

3. Equipment functional characteristics

1. From the knowledge of the verification document to the knowledge of comprehensive application books. Experimental and tr--ning arrangements are dominated by tr--ning capabilities and technical applications as the goal, which is close to production reality.

2. Students independently set up experimental and tr--ning circuits. Various modules are carefully configured. There are multiple application components. The modules use transparent organic boxes and are also used as physical teaching. There are 156 electrical electronic unit modules, including not only the units required for the tr--ning guidance project, but also the innovative and exploration that the students may conduct, and configure a relatively complete unit.

3. The device provides a variety of power and signal sources, as well as various instruments, and provides students with a platform that is fully open and can give full play to the potential of innovation. For the reason, you can also do skill competitions, curriculum design, graduation design and technological development; and the module is convenient, you can let the students operate and test without worries.

Electronic product design and production tr--ning device,Elevator well track facilities installation and debug tr--ning device

1. Product overview

This device is a platform for elevator wells to put and install tr--ning assessment based on the current real elevator well -tract system and m--ntenance needs. Elevator installation and m--ntenance, building automation, mechanical qualification appr--sal centers and tr--ning assessment institutions for elevator installation and m--ntenance, building automation, mechanical and electrical automation, and tr--ning and assessment institutions are suitable for each vocational college and technical schools.

Elevator car disassembly tr--ning device adopts real elevator floor gate, car guide r--l, car rack, car, car door, car buffer, p--r of heavy r--ls, heavy racks, fences, p--rs, p--rs, p--rs For heavy blocks, to entert--n devices and other devices, students use the elevator well tr--l system to design drawings on the top of the analogway and install and measure the well -running equipment in order to meet the requirements of the specifications. The upper and lower motion simulates its operation on the well -track guide and auxiliary inspection of the actual installation quality of the guide r--l.

2. Product characteristics

1. The design of the steel structure elevator well road platform is adopted, and the overall appearance is simple and clear;

2. Follow the modular design concept, and conduct teaching and tr--ning design according to the requirements of the elevator installation process;

3. Use real institutional devices to make students learn consistent with practical applications;

4. Simten to the real environment, make it consistent with the installation process as the actual installation, and can operate its m--ntenance project more conveniently;

5. Adopt a manual gourd dragging the car rack and the movement of the heavy rack on the guide r--l, making the demonstration and debugging more convenient.

6. Genuine elevator car 3D simulation disassembly teaching software

Software is based on an independent virtual experiment 3D environment. No need to rely on any third party virtual environment

- Previous:Electronic technology training device

- Next:Car ABS Electrical Control System Teaching and Training Device

Recommended information

Recommended Products