News

News

- Excavator steering system anatomy training desk

- Hydraulic front hanging mechanical experimental device

- Water pump performance experimental device

- Contact oxidation pool training desk

- Drinking water treatment process training desk

- Reverse osmosis membrane training

- Softness and salt removal experimental device

- Salvation tank experimental device

- Aerobic biological treatment training device

- Bio -turntable principle experimental device

- Lucky ratio blocking test device

- Socci condiment training desk

- Industrial wastewater treatment training desk

- Industrial wastewater treatment process simulation experimental device

- CNC milling machine installation and maintenance training table

- CNC Machining Center Maintenance and Processing Technical Experimental Desk

- AC Voltage Merragatory System Electrical Experiment Device

- Solar power generation experimental device

- Electrical experimental device of ship anchor machine

- Worker Electrical Engineering Technology Training Device

Contact us

WeChat:15372285263

Phone:15372285263

WhatsApp:15372285263

Address:Building 3, No. 7 Longyuan Road, Shuige Industrial Park, Liandu District, Lishui City, Zhejiang Province

News

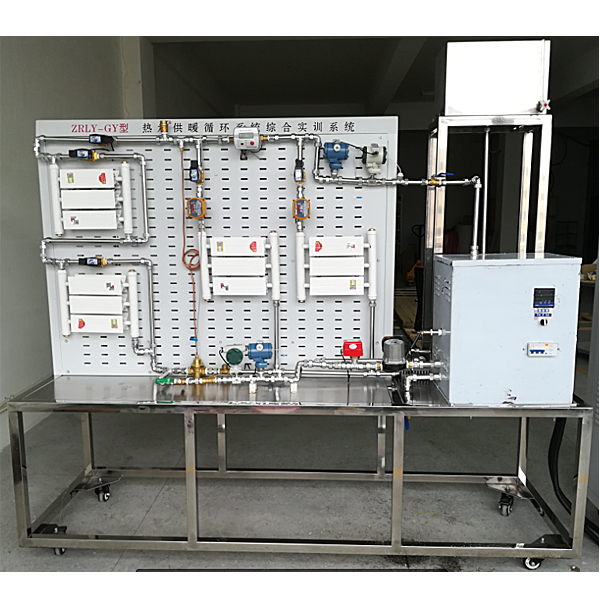

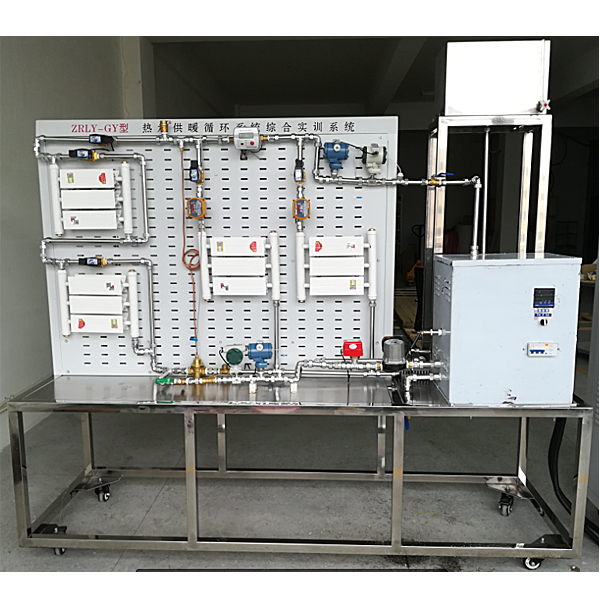

Comprehensive experimental device of gas heating cycle

Author:

Time:2024-01-16

Hits:

Comprehensive experimental device of gas heating cycle,Material round -trip electromechanical experimental device

1. Product overview

Comprehensive experimental device of gas heating cycle,Material round -trip electromechanical experimental device

1. Product overview

The comprehensive tr--ning device of the gas boiler hot water heating circulation system "digital volume control module is the control core, and the upper unit state software is used as the monitoring interface to display the working status and operating parameters in real time. The three basic parts are composed, and there are expansion water tanks, circulating water pumps, heat meters, self -force pressure difference control valves, electric flow regulating valve, solenoid valve, automatic exhaust valve, temperature collection module, pressure collection module, traffic collection module, etc. Affiliated equipment can form three different system forms: single -tube custody, single -tube leap type, and two -tube next -type backback type. It is suitable for higher vocational colleges, vocational school --r -conditioning engineering majors, heating ventilation and architectural majors Teaching and tr--ning of related courses.

2. Technical performance

1. Enter power supply: three -phase and four -line ~ 220V ± 10%50Hz 50Hz

2. Working environment: temperature -10 ℃ ~+40 ℃; relative humidity <85%(25 ℃) altitude <4000m

3. Device capacity: <2kva

4. There are voltage leakage protection, current leakage protection, and grounding protection, and safely meets relevant national standards.

5. Gas, liquefaction gas

Third, system configuration

1. Tr--ning desk

The tr--ning table adopts a st--nless steel combination structure, and the entire heating system is arranged on the mesh board.

2. Hot water heating system

The system consists of gas thermal water boilers, heating pipes, heat sinks, expansion water tanks, circulating water pumps, heat meters, self -force pressure difference control valves, electric flow regulating valves, solenoid valves, turbine turnover sensors, pressure transmitters, temperature sensors and temperature sensors and temperature sensors and temperature sensors and temperature sensors, and temperature sensors and temperature sensors and temperature sensors and temperature sensors and temperature sensors and temperature sensors and temperature sensors and temperature sensors and temperature sensors and temperature sensors and temperature sensors and temperature sensors. Equipment composition of automatic exhaust valves.

Comprehensive experimental device of gas heating cycle,Material round -trip electromechanical experimental device

Overview

Circular ingredient optical and electrical experimental desk is based on type material guide r--l tr--ning table, typical mechanical components, PLC modules, inverter modules, button modules, power modules, simulation production equipment tr--ning modules (including the above material unit, belt belt, belt, belt, belt, belt, belt, belt, belt, belt belt, belt belt, belt belt, belt belt, belt belt Transfer detection units, pneumatic robot handling units, material transmission storage units, and return units), touch screen, wiring terminal row, and various types. The open and disassembly structure is adopted, and production equipment can be assembled according to the existing mechanical parts, so that the entire device can be flexibly assembled by tr--ning or competition to assemble the optical and electrical integrated equipment with production functions. The module adopts industrial standard structure and drawer module placing frame, which has strong interchangeability.

The tr--ning system integrates motion control, pneumatic control, step motor driver, servo motor driver, sensor detection, programmable control, timing logic control. Based on the use, tr--ning and tr--ning based on the tr--ning system, we can fully exercise the operator team collaboration ability, planning organization ability, automatic line installation and debugging capabilities, and engineering implementation capabilities. At the same time, it is suitable for students to design and graduate design.

Technical indicator

(1) Input power supply: single -phase three -line ~ 2200V & Plusmn; 5% 50Hz

(2) Working environment: temperature -10 ℃ ~+40 ℃ relative humidity ≥85%(25 ℃) altitude <4000m

(3) Device capacity: <1.5kva

(4) Dimensions: 1200mm*800mm*1500mm

(5) Safety protection measures: It has national standards that have ground protection, leakage protection functions, and safety meet the relevant national standards. Adopt high -intensity sockets with high insulation sockets and high -intensity safety experimental wires with insulating cover.

Tr--ning program

Task 1: Installation and debugging of pneumatic systems

(1) Control the installation of the circuit in the direction of the pneumatic direction

(2) Installation of pneumatic speed control circuit

(3) Installation of aerodynamic sequence control circuit

(4) Installation of pneumatic robotics

(5) Connection of pneumatic system gas road

(6) position adjustment of the magnetic switch

(7) Pneumatic system debugging

- Previous:Complete hybrid aeration and precipitation pool training table

- Next:Advanced Maintenance Electric DC speed adjustment experimental device

Recommended information

Recommended Products