News

News

- Excavator steering system anatomy training desk

- Hydraulic front hanging mechanical experimental device

- Water pump performance experimental device

- Contact oxidation pool training desk

- Drinking water treatment process training desk

- Reverse osmosis membrane training

- Softness and salt removal experimental device

- Salvation tank experimental device

- Aerobic biological treatment training device

- Bio -turntable principle experimental device

- Lucky ratio blocking test device

- Socci condiment training desk

- Industrial wastewater treatment training desk

- Industrial wastewater treatment process simulation experimental device

- CNC milling machine installation and maintenance training table

- CNC Machining Center Maintenance and Processing Technical Experimental Desk

- AC Voltage Merragatory System Electrical Experiment Device

- Solar power generation experimental device

- Electrical experimental device of ship anchor machine

- Worker Electrical Engineering Technology Training Device

Contact us

WeChat:15372285263

Phone:15372285263

WhatsApp:15372285263

Address:Building 3, No. 7 Longyuan Road, Shuige Industrial Park, Liandu District, Lishui City, Zhejiang Province

News

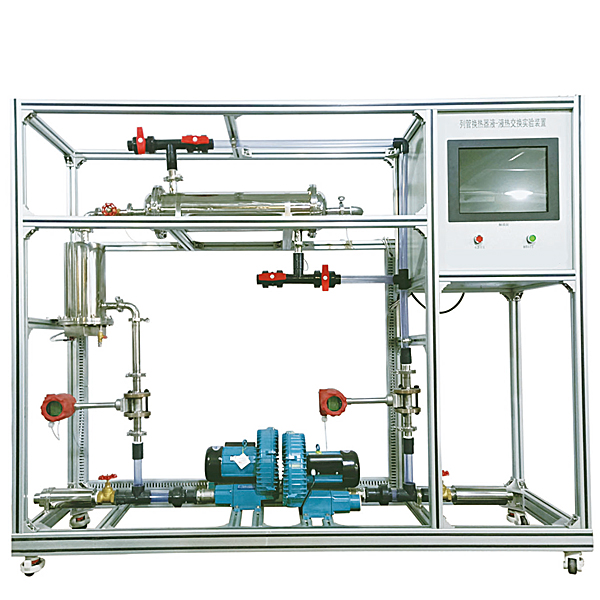

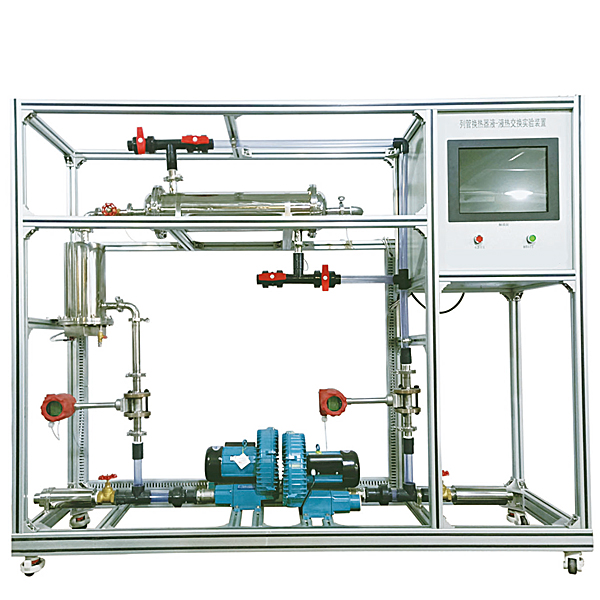

Tube heat exchanger gas-gas heat exchange experimental device

Author:

Time:2024-01-14

Hits:

Tube heat exchanger gas-gas heat exchange experimental device,Plane and Space Institution Experiment

Feature

Tube heat exchanger gas-gas heat exchange experimental device,Plane and Space Institution Experiment

Feature

1. The entire device is beautiful and generous, the structure is reasonable, the overall sense is strong, and has a strong engineering atmosphere, which can fully reflect the concept of modern laboratories.

2. The device is a self -propelled frame structure, and the feet are installed, which is convenient for the system's disassembly, m--ntenance and handling, and reflects the perfectness of the entire device.

3. The test device of the heat coefficient measurement is based on the hot and cold --r as the medium. The gas-gas exchange thermal system is used, the data measurement is accurate, the experimental effect is ideal, and the degree of automation is high.

4. The device uses a tube heat exchanger for hot and cold gas to change heat. The cold --r uses --r instead of water, saving water resources. The design of the dual fan owner and deputy circuit design, the switching of the heating process ag--nst the current, is closer to the reality of industrial applications.

5. Use the thyristor pressure regulating module to control the power of heating room. Multiple sets of U -shaped fins heating pipe preheating system, fast and uniform heating speed, platinum heat resistance+thyristor+heating pipe as the m--n control method of thermal flow temperature Essence

6. Device design can be observed at 360 degrees to achieve comprehensive teaching and experiments.

Device function

1. Understand the structure and processes of the pipe tube exchanges, and master the experimental methods for the measurement of the thermal coefficient.

2. Compare the process and effect of the heating device of the pipe tube and the heat exchange experiment.

3. Measure the heat transfer coefficient of the heat exchanger for the heat conveyor;

4. The impact of reverse and streaming operations on the average driving force and heat transfer coefficient of heat exchangers, respectively.

5. Integrated control, high -stable data transmission, hardware encryption.

6. The device can realize the mobile terminal scanning, and obt--n the device three -dimensional process video introduction.

Design Parameters

Cold flow (--r) flow: 0 ~ 40m3/h. Cold flow (--r) temperature: normal temperature ~ 50 ℃.

Heat (--r) flow: 0 ~ 40m3/h. Heat (--r) temperature: 80-110 ° C.

Tube heat exchanger gas-gas heat exchange experimental device,Plane and Space Institution Experiment

I. Overview

This experimental platform is carefully designed on the basis of absorbing the advantages of similar devices in the domestic religious market. It sets flexible construction, convenient assembly, and showing a beautiful integration. It is a platform for innovative designs for universities for innovative design of plane sports institutions for mechanical teachers and students of colleges and universities.

2. M--n features

1. According to the principle of the composition of the institution and the principle of the pole group (including the high -side rod group), it can enable students to further grasp the theory of institutional composition through experiments. Familiar with the basic knowledge of the concept of rod group and mechanical transmission, laying a good foundation for innovative design Items

2. The transmission system that can compose a plane with different performances and space, which is conducive to cultivating the design capacity of the student institution's transmission system scheme;

3. This experimental device has a clear level of the transmission system, reliable connection, and no motion interference or detachment between components, and can be manual or electric;

4. This experimental device and connection method are clever design, large use range, easy and convenient disassembly, compact structure, good universality between components, and many assembly solutions.

5. The experimental desk is flexible and convenient for the assembly and adjustment, and the size of each pole is accurate;

6. The experimental table can assemble more than 40 kinds of institutions. The assembly institutions can exercise flexibly and have no stagnation interference.

7. Machinery assembly and fitter assembly virtual simulation software: This software is developed based on Unity3D. It can select 6 -level image quality. It has the design and virtual disassembly of the reducer and shaft structure, the design and simulation of common mechanical institutions, institutional resource libraries, institutional resource libraries. Typical mechanical institutions (virtual disassembly of gasoline engines), software is an overall software, which cannot be separate resources.

- Previous:Hydraulic pump valve performance test training device

- Next:Digital fluidized bed drying experiment table

Recommended information

Recommended Products