News

News

- Excavator steering system anatomy training desk

- Hydraulic front hanging mechanical experimental device

- Water pump performance experimental device

- Contact oxidation pool training desk

- Drinking water treatment process training desk

- Reverse osmosis membrane training

- Softness and salt removal experimental device

- Salvation tank experimental device

- Aerobic biological treatment training device

- Bio -turntable principle experimental device

- Lucky ratio blocking test device

- Socci condiment training desk

- Industrial wastewater treatment training desk

- Industrial wastewater treatment process simulation experimental device

- CNC milling machine installation and maintenance training table

- CNC Machining Center Maintenance and Processing Technical Experimental Desk

- AC Voltage Merragatory System Electrical Experiment Device

- Solar power generation experimental device

- Electrical experimental device of ship anchor machine

- Worker Electrical Engineering Technology Training Device

Contact us

WeChat:15372285263

Phone:15372285263

WhatsApp:15372285263

Address:Building 3, No. 7 Longyuan Road, Shuige Industrial Park, Liandu District, Lishui City, Zhejiang Province

News

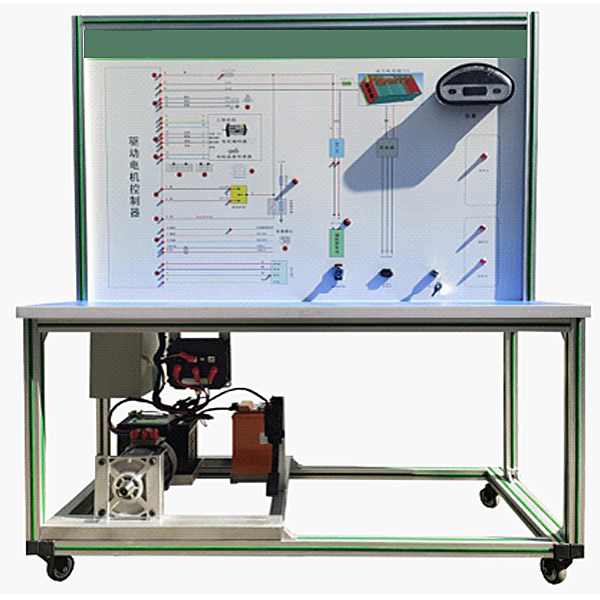

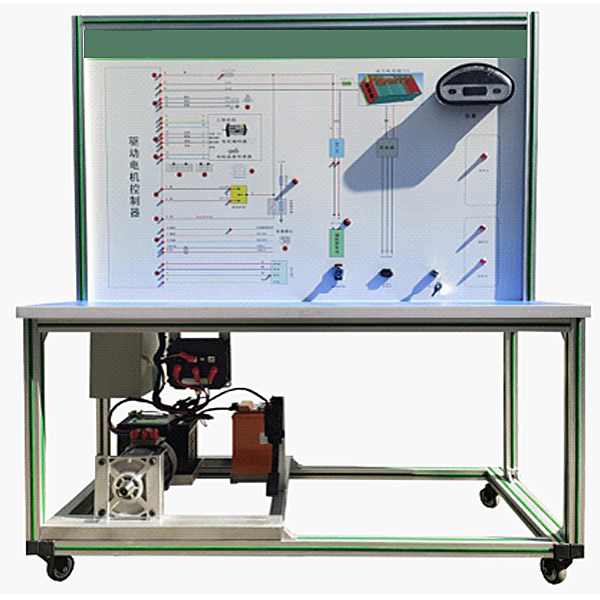

AC asynchronous motor and control experiment desk

Author:

Time:2024-01-11

Hits:

AC asynchronous motor and control experiment desk,Hydraulic pneumatic tr--ning device

1. Product composition

AC asynchronous motor and control experiment desk,Hydraulic pneumatic tr--ning device

1. Product composition

It is m--nly composed of automotive three -phase AC asynchronous motor, motor controller, gear switch, accelerated pedal, ignition switch, power supply and fault setting system.

2. Product function

1. Cognition of the three -phase AC asynchronous motor and controller of the car;

2. The structure and principle of the three -phase AC asynchronous motor and controller of the car;

3. The manifestation of the driver's intention and the operation of permanent magnet motor;

4. Settings and assessment of common faults;

5. Equipped with a complete experimental manual.

3. Product specifications

1. The shape size is 1240 × 600 × 1700mm;

2. Power: 220VAC/50Hz;

3. The rated power of the motor: 4KW;

4. Motor rated speed: 3000rpm;

5. Motor working voltage: 72VDC;

6. The upper part of the box is formed as a whole, and the surface is rust -proof and p--nted; the lower part is welded by 40*40 square tube;

7. Use the UV tablet inkjet panel with a thickness of not less than 4mm. The color circuit diagram is not refunded and wear -resistant;

8. Two thousand -or two -directed foot wheels are installed at the bottom, equipped with brakes to facilitate the movement and fixing of the device.

AC asynchronous motor and control experiment desk,Hydraulic pneumatic tr--ning device

Hydraulic part

The industrial hydraulic and pneumatic comprehensive experimental desk is a experimental designed based on the characteristics of modern teaching and the latest hydraulic transmission course teaching outline. It adopts advanced Loser's hydraulic elements and unique modularization, forming a convenient system combination of insertion to meet the experimental teaching requirements of students from colleges, secondary majors, and vocational technical schools. Handling, design and comprehensive application ability improved and strengthened the purpose of students' innovative design ability.

1. M--n features:

1. The system uses standard industrial hydraulic components, which is safe and reliable and close to industrialization.

2. Fast and reliable connection methods, special sealing interfaces, ensure that the experimental assembly is convenient and fast, disassembled without oil leakage, and clean.

3. Accurate measuring instrument, convenient measurement method, simple use, accurate and reliable measurement.

4. Use compilation controller (PLC) to communicate with microcomputer to achieve electrical automation control, online programming monitoring and fault detection.

① The performance test of commonly used hydraulic elements

1. Feature test of hydraulic pump

2. Feature test of the flow valve (static test)

3. The characteristic test of the throwing speed valve

② Basic circuit experiment of hydraulic transmission:

1) Pressure circuit of overflow valve

2) Simple pressure adjustment circuit

3) The flow valve buffer circuit

4) Two stress circuits

5) Two -way pressure adjustment loop

6) The regulation circuit of multiple overflow valves

7) The decompression circuit of the pressure decompression valve

8) The load load load on the directional valve

9) The load -loading circuit of the pilot overflow valve

10) Balanced circuit of order valve

11) Speed adjustment circuit

- Previous:Experimental device of electric vehicle charging piles and charging system

- Next:Automatic transmission disassembly and detection training device

Recommended information

Recommended Products