News

News

- Excavator steering system anatomy training desk

- Hydraulic front hanging mechanical experimental device

- Water pump performance experimental device

- Contact oxidation pool training desk

- Drinking water treatment process training desk

- Reverse osmosis membrane training

- Softness and salt removal experimental device

- Salvation tank experimental device

- Aerobic biological treatment training device

- Bio -turntable principle experimental device

- Lucky ratio blocking test device

- Socci condiment training desk

- Industrial wastewater treatment training desk

- Industrial wastewater treatment process simulation experimental device

- CNC milling machine installation and maintenance training table

- CNC Machining Center Maintenance and Processing Technical Experimental Desk

- AC Voltage Merragatory System Electrical Experiment Device

- Solar power generation experimental device

- Electrical experimental device of ship anchor machine

- Worker Electrical Engineering Technology Training Device

Contact us

WeChat:15372285263

Phone:15372285263

WhatsApp:15372285263

Address:Building 3, No. 7 Longyuan Road, Shuige Industrial Park, Liandu District, Lishui City, Zhejiang Province

News

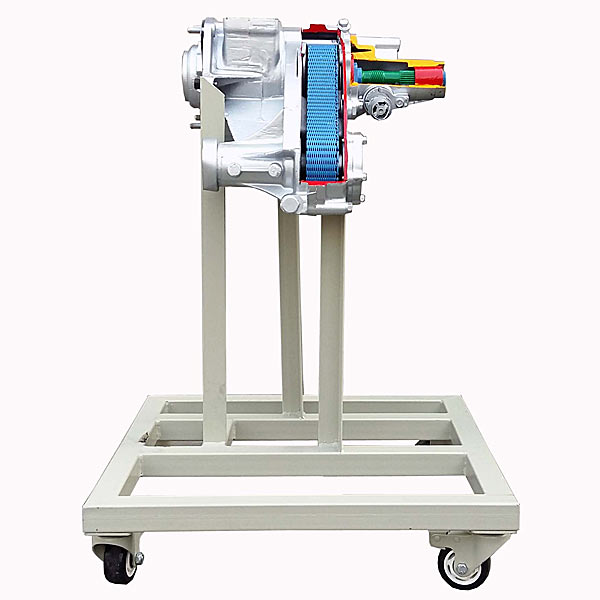

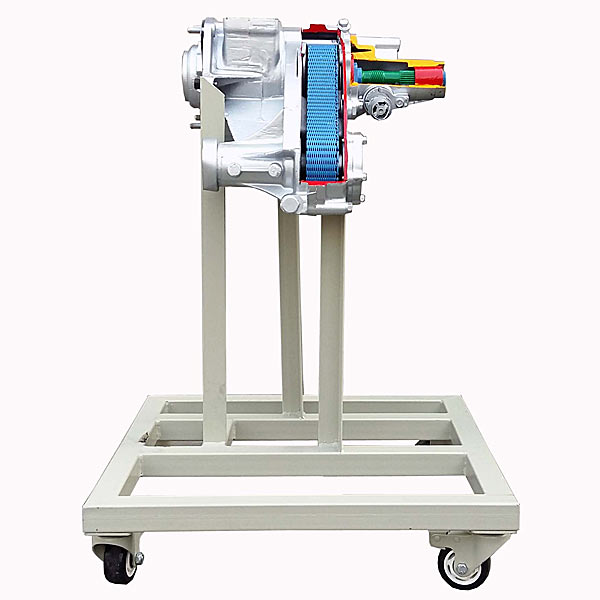

Disassenger disassembly and assembly experimental device

Author:

Time:2024-01-08

Hits:

Disassenger disassembly and assembly experimental device,Pressure sensor calibration experimental device

1. Function Introduction

Disassenger disassembly and assembly experimental device,Pressure sensor calibration experimental device

1. Function Introduction

1. Use the divisioner assembly (complete accessories, easy to disassemble), and install it on a special table. Students disassemble and assemble from different angles.

2. The tablet uses high -intensity steel structure welding, and the surface is sprayed on the surface. There is a self -locking foot wheel at the bottom of the tablet, which can be moved for easy teaching.

two. Technical specification

Equipment shape: 300 × 300 × 700mm (length × width × height)

Color: 7032

Steel pipe: 40*40*3mm

Universal foot wheel

The first two universal band lock function foot wheels

2 After the two thousand -facing foot wheels

The foot wheel and the table frame are fixed with the M6*4 screws, which is convenient for equipment m--ntenance and m--ntenance.

Foot wheel: 60mm × 50mm (diameter × width)

Foot wheel support: 1.0T

Disassenger disassembly and assembly experimental device,Pressure sensor calibration experimental device

Pressure measurement equipment is widely used in engineering, with a wide variety of types. The calibration of key component pressure sensors for pressure measurement equipment is the most important part of ensuring equipment accuracy. Therefore, the pressure sensor calibration experiment is an important part of the course teaching of "Thermal Work Inspection Technology". Through this experiment, it can deepen the students' understanding of the theory of automatic detection technology, so that students can better learn this basic course of this project to understand the dynamic response characteristics of sensor dynamic response characteristics The importance and measurement and processing methods of dynamic pressure measurement. In this experimental desk, a piston static pressure power verification equipment is used at the same time to check the industrial far -pass pressure gauge and the static and dynamic pressure of the pressure sensor installed in the same pressure chamber; The above pressure sensors measure this pressure signal at the same time, and measure the dynamic characteristics of each pressure sensor. The output of each pressure sensor is collected and analyzed by the computer to deepen the students' understanding of pressure detection technology and improve the ability to use microcomputer to analyze static and dynamic performance analysis of each pressure sensor. This experimental desk is advanced technology, suitable for product quality inspection and teaching and scientific research of manufacturers.

1. Experimental purpose

(1) Master the method and equipment of the characteristic calibration of the pressure sensor;

(2) Understand the dynamic response characteristics of different pressure sensors;

(3) Analyze the dynamic pressure response characteristics of various pressure sensors;

(4) Master the application of basic signal processing technology.

Based on standards

1. GB/T1526-1989 "Information processing data flowchart, program flow diagram, system flowchart, program network diagram, system resource diagram file preparation symbol and agreement";

2. GB/T8567-1988 "Guidelines for Development File Development File";

3. GB50171-92 "Electric Device Installation Engineering Disk, Cabinet and Secondary Circuit Construction and Acceptance Specifications";

4. ZB/N04009-88 "Industrial Automation Instrument Plate Common Technical Conditions".

- Previous:Car steering system disassembly training device

- Next:Ventilation and smoke -proof test experimental device

Recommended information

Recommended Products