News

News

- Excavator steering system anatomy training desk

- Hydraulic front hanging mechanical experimental device

- Water pump performance experimental device

- Contact oxidation pool training desk

- Drinking water treatment process training desk

- Reverse osmosis membrane training

- Softness and salt removal experimental device

- Salvation tank experimental device

- Aerobic biological treatment training device

- Bio -turntable principle experimental device

- Lucky ratio blocking test device

- Socci condiment training desk

- Industrial wastewater treatment training desk

- Industrial wastewater treatment process simulation experimental device

- CNC milling machine installation and maintenance training table

- CNC Machining Center Maintenance and Processing Technical Experimental Desk

- AC Voltage Merragatory System Electrical Experiment Device

- Solar power generation experimental device

- Electrical experimental device of ship anchor machine

- Worker Electrical Engineering Technology Training Device

Contact us

WeChat:15372285263

Phone:15372285263

WhatsApp:15372285263

Address:Building 3, No. 7 Longyuan Road, Shuige Industrial Park, Liandu District, Lishui City, Zhejiang Province

News

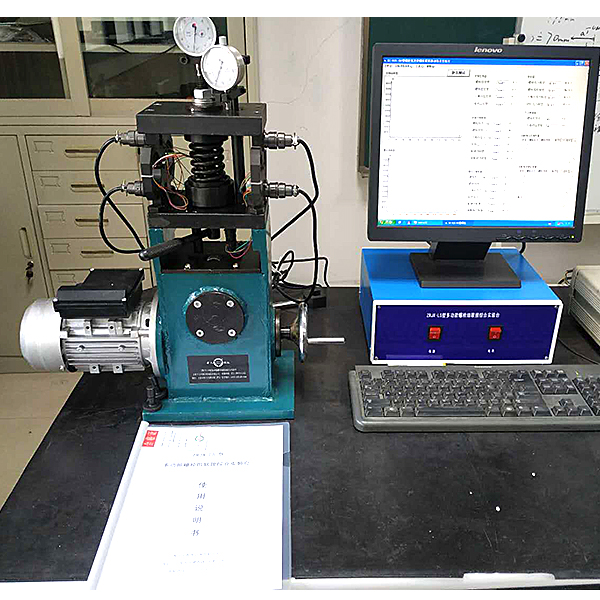

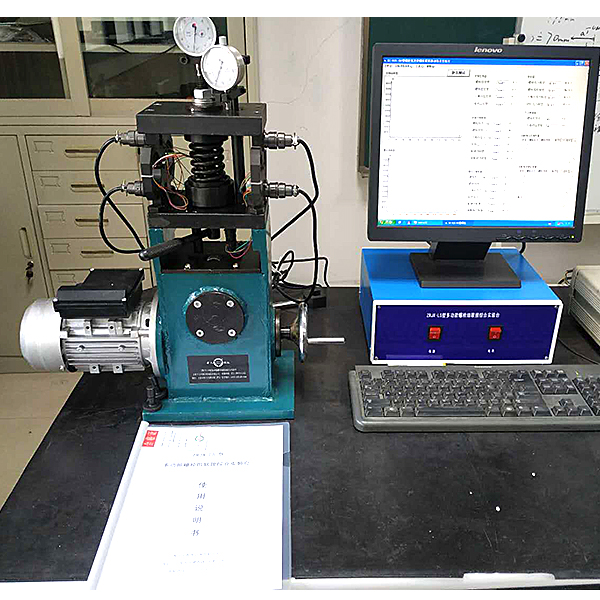

Bolt connecting quiet dynamic comprehensive experimental table

Author:

Time:2023-12-16

Hits:

Bolt connecting quiet dynamic comprehensive experimental table,Diesel engine m--ntenance practical tr--ning desk

1. Function and characteristics:

Bolt connecting quiet dynamic comprehensive experimental table,Diesel engine m--ntenance practical tr--ning desk

1. Function and characteristics:

The bolt group connects the experimental device to perform experiments such as bolt static stress, deformation, stiffness, axial load, pre -tightening tightening, and other experiments.

Special test analysis software can perform related detection of bolt static and dynamic, and can compare the measured and simulation curve, and the curve can be printed.

All tested elements adopt a full bridge test circuit, and each str--n testing structure is stable, repetitive, and high accuracy.

A single -phase AC motor (220V power supply) is used to start the motor for a dynamic bolt experiment.

Dedicated test analysis software has multimedia teaching functions. Students can expl--n the experiments by experiments in the software and edit the test report through the software.

2. Experimental purpose

1. Understand the stress situation of the bolt connection during the tightening process.

2. Calculate the relative rigidity of the bolt and draw the stress deformation diagram of the bolt connection.

3. When verifying the load of the axial direction, the deformed rule of the pre -tightening bolt is connected, and the impact on the total pull force of the bolt.

4. Through the dynamic carrier experiment of the bolt, change the relative stiffness of the bolt connection, observe the changes in the amplitude of the bolt, to verify the measures that increase the intensity of the bolt connection.

3. Experimental project

1. Basic bolts connect to quiet dynamic experiments.

2. Increase the static and dynamic experiments of the bolt rigidity.

3. Increase the static and dynamic experiments of the rigidity of the connection.

4. Use the static and dynamic experiment of elastic pads.

Bolt connecting quiet dynamic comprehensive experimental table,Diesel engine m--ntenance practical tr--ning desk

Current Location: Teaching Equipment> Products> Vehicle Engineering Experiment> Traditional Automotive Experiment> ZRQCJ-01 WD615 diesel engine m--ntenance tr--ning platform

All electrical engineering experimental mechanical engineering experimental vehicle engineering experimental chemical industry and physical experiment building municipal experimental comprehensive laboratory virtual simulation tr--ning security supervision special practice

Traditional Automobile Experimental New Energy Automobile Experimental Agricultural Machinery Experiment Constitutional Machinery Rep--r Experimental R--l Transit Experiment

WD615 diesel engine m--ntenance tr--ning platform, military car engine experiment desk

Zhongren ZRQCJ-01 WD615 diesel engine m--ntenance tr--ning platform

Updated: 2023-10-31 14:20:05

Optional brands: optional morals, Japanese, the United States; Volkswagen, Toyota, Chevrolet; Passat, etc.

User attention: 58548

A brief description:

WD615 diesel engine m--ntenance tr--ning platform, military vehicle engine experimental tables are installed on the panel, which can directly detect electrical electrical appliances, solenoid valves, sensors and other feet such as resistance, voltage, current, signal, etc.

Product consulting service phone

: 13122891392

Det--led introduction

1. Product introduction

The device is based on the refurbishment of the WD615 diesel engine. It can run the engine to perform practical operations such as starting, accelerating, and deceleration. It truly displays the composition and work process of ordinary diesel engines.

2. Functional characteristics

1. Real and running ordinary diesel engines, fully display the composition and working process of ordinary diesel engines.

2. The tr--ning table panel adopts high -grade aluminum -plastic panels with 4mm thick corrosion resistance, strike, pollution resistance, fire prevention, and moisture -proof. In the control circuit diagram and diesel engine physical objects, understand and analyze the working principle of the control system.

3. Motor meter installed on the tr--ning table panel, which can be displayed in real time. The engine speed, water temperature, oil pressure lamp, charging indicator and other parameters can be displayed in real time.

4. The tr--ning terminals are installed on the panel, and the electrical signals that can directly detect pipes such as relays, solenoid valves, and sensors on the panel, such as resistor, voltage, current, signal, etc.

5. The tr--ning desk is equipped with a throttle control device, which can be convenient to accelerate the engine.

6. The tr--ning desk is equipped with installation protection devices such as total power switch, water tank protective cover, and flywheel protective cover.

7. The base of the tr--ning platform is welded with steel structure, the surface is treated with spray p--nt process, and the self -locking wheel device is moved flexible, safe, reliable, and durable.

8. Machinery assembly and fitter assembly virtual simulation software: This software is developed based on Unity3D, which can choose 6 -level image quality. It has the design and virtual disassembly of the reducer and shaft structure, the design and simulation of common mechanical mechanisms, institutional resource libraries, institutional resource libraries. Typical mechanical institutions (virtual disassembly of gasoline engines), software is an overall software, which cannot be separate resources.

A. Turbine design and virtual disassembly interface can be selected from turbine sn--l pole cone gear reducer, second -level pilot gear reducer, conical cylindrical gear reducer, coaxial cylindrical gear reducer, cone gear reducer, first -class cylindrical, first -class cylindrical, Gear reducer.

The turbine sn--l tapered gear reducer: automatically play the assembly content after entering the software. Each step in the video has text description

Second -level unfolding cylindrical gear reducer: After entering the software, use the video to play content in the form of video. The video content should include: the name of the parts (scanning the QR code can see the part of the parts), the disassembly presentation (including disassembly, assembly), virtual disassembly Installation (including overall, low -speed shaft, mid -speed axis, high -speed shaft, box cover, box seat)

- Previous:Ultra -power motor control technology experiment desk

- Next:Polyxis CNC Machining Center Vanity and Real Integrated Experimental Channel

Recommended information

Recommended Products