Product

News

- Excavator steering system anatomy training desk

- Hydraulic front hanging mechanical experimental device

- Water pump performance experimental device

- Contact oxidation pool training desk

- Drinking water treatment process training desk

- Reverse osmosis membrane training

- Softness and salt removal experimental device

- Salvation tank experimental device

- Aerobic biological treatment training device

- Bio -turntable principle experimental device

- Lucky ratio blocking test device

- Socci condiment training desk

- Industrial wastewater treatment training desk

- Industrial wastewater treatment process simulation experimental device

- CNC milling machine installation and maintenance training table

- CNC Machining Center Maintenance and Processing Technical Experimental Desk

- AC Voltage Merragatory System Electrical Experiment Device

- Solar power generation experimental device

- Electrical experimental device of ship anchor machine

- Worker Electrical Engineering Technology Training Device

Contact us

WeChat:15372285263

Phone:15372285263

WhatsApp:15372285263

Address:Building 3, No. 7 Longyuan Road, Shuige Industrial Park, Liandu District, Lishui City, Zhejiang Province

Chemical Fluid

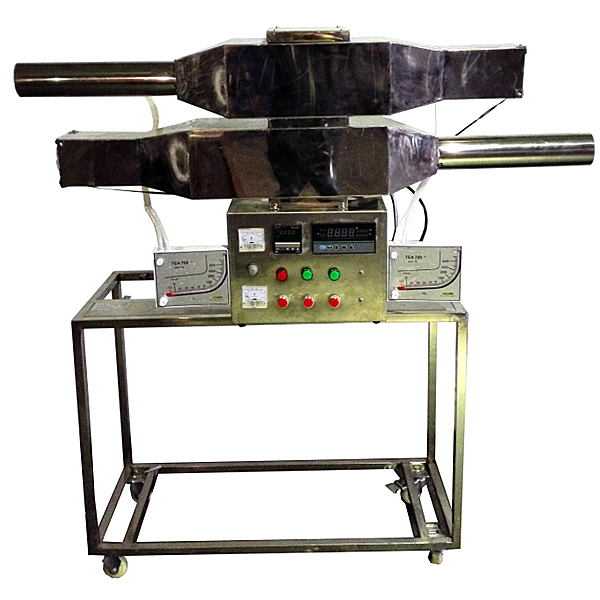

zopHGRG-20 heat pipe heat exchanger experimental platform

Heat pipe heat exchanger test bench, heat pipe heat exchanger heat transfer coefficient training device heating section air duct, heated section air duct, fan, Pitot tube flowmeter and differential pressure sensor, heating is steplessly regulated by solid pressure regulating module, universal signal input inspection instrument displays temperature, pressure difference, ammeter, voltage.

Technical parameters:

1. Input power: single-phase AC220V±10% 50Hz, power 500W.

2. Low-noise axial flow fan, power: 100W, flow rate: 300 m3/h.

3. Pitot tube flowmeter with inclined tube micromanometer to measure flow rate: range -10-700pa.

4. The diameter of the cold and hot end velocity measurement section duct is Φ89mm; finned (aluminum rolled tube) heat pipe heat exchanger, size Φ20×350mm, material copper tube.

5. Temperature measurement: The measurement system is equipped with an intelligent temperature control instrument (PID temperature control, accuracy ±0.2℃), and a high-precision PID voltage regulation module circuit.

6. Dimensions: 1000×400×800mm, the appearance is a st*nless steel bracket.

7. Virtual simulation software for electrical installation of building buildings and intelligent buildings Based on unity3d design, users can choose different sizes of interactive interfaces according to computer configuration, and can choose six levels of image quality. The model in the software can be rotated 360°, enlarged, reduced, and translated. There are assistant prompts during the use of the software, as follows: A. Wet alarm system 1. System overview: Overview of wet alarm system 2. Equipment recognition: It has the best viewing angle, equipment det*ls (displaying the introduction or parameters of the equipment), exercises (6 built-in multiple-choice questions, with prompts for correct and incorrect choices), and schematics (you can enter the equipment from the schematics). The equipment includes: sprinklers, water flow indicators, signal butterfly valves, exhaust valves, fire alarm controls, high-pressure gauges, high-level water tanks, Wia control cabinets, pressure regulators, flow switches, terminal water testing devices, dr*nage facilities, water pump connectors, hydraulic alarms, delays, wet alarms, butterfly valves, check valves, fire pumps, safety pressure regulators, and fire water tanks. 3. Principle display: Display the working principle of the wet alarm system, 3D animation demonstration, and semi-transparent 3D models, so you can see the internal water flow. Equipped with practice module (built-in 4 multiple-choice questions, with prompts for correct and wrong choices) 4. Design layout: There are multiple-choice questions and calculation questions, each of which is scored, and the correct answer and score will be displayed after submission B. Gas fire extinguishing system 1. System overview: Overview of gas fire extinguishing system 2. Equipment cognition: It is equipped with the best viewing angle, equipment det*ls (displaying the introduction or parameters of the equipment), practice (built-in 8 multiple-choice questions, with prompts for correct and wrong choices), schematic diagram (you can enter the equipment from the schematic diagram). The equipment includes: nozzle, HFC-227 storage bottle, bottle head valve, heptafluoropropane check valve, high-pressure hose, gas check valve, safety valve, weighing alarm, electromagnetic starter, selection valve, smoke alarm, fire alarm controller. 3. Principle display: Display the working principle of the gas fire extinguishing system, 3D animation demonstration, 3D model is semi-transparent, and the internal gas can be seen. Equipped with a practice module (3 multiple-choice questions built in, with prompts for correct and incorrect choices) 4. Design layout: There are 6 multiple-choice questions, each with a score, and the correct answer and score will be displayed after submission C. Escape drill: Teaching in the form of fun games, escape from the burning room within a limited time, and wrong choices will directly enter the score interface. Experimental purpose: 1. Understand the structure of the heat pipe heat exchanger. 2. The heat transfer coefficient and thermal efficiency of the heat pipe heat exchanger can be calculated. M*n configuration: heat pipe heat exchanger, heating section *r duct, heating section *r duct, fan, Pitot tube flowmeter and differential pressure sensor , heating is steplessly adjusted by a solid pressure regulating module, universal signal input patrol meter displays temperature, pressure difference, ammeter, voltmeter, st*nless steel stand and control screen, etc.

1. Input power: single-phase AC220V±10% 50Hz, power 500W.

2. Low-noise axial flow fan, power: 100W, flow rate: 300 m3/h.

3. Pitot tube flowmeter with inclined tube micromanometer to measure flow rate: range -10-700pa.

4. The diameter of the cold and hot end velocity measurement section duct is Φ89mm; finned (aluminum rolled tube) heat pipe heat exchanger, size Φ20×350mm, material copper tube.

5. Temperature measurement: The measurement system is equipped with an intelligent temperature control instrument (PID temperature control, accuracy ±0.2℃), and a high-precision PID voltage regulation module circuit.

6. Dimensions: 1000×400×800mm, the appearance is a st*nless steel bracket.

7. Virtual simulation software for electrical installation of building buildings and intelligent buildings Based on unity3d design, users can choose different sizes of interactive interfaces according to computer configuration, and can choose six levels of image quality. The model in the software can be rotated 360°, enlarged, reduced, and translated. There are assistant prompts during the use of the software, as follows: A. Wet alarm system 1. System overview: Overview of wet alarm system 2. Equipment recognition: It has the best viewing angle, equipment det*ls (displaying the introduction or parameters of the equipment), exercises (6 built-in multiple-choice questions, with prompts for correct and incorrect choices), and schematics (you can enter the equipment from the schematics). The equipment includes: sprinklers, water flow indicators, signal butterfly valves, exhaust valves, fire alarm controls, high-pressure gauges, high-level water tanks, Wia control cabinets, pressure regulators, flow switches, terminal water testing devices, dr*nage facilities, water pump connectors, hydraulic alarms, delays, wet alarms, butterfly valves, check valves, fire pumps, safety pressure regulators, and fire water tanks. 3. Principle display: Display the working principle of the wet alarm system, 3D animation demonstration, and semi-transparent 3D models, so you can see the internal water flow. Equipped with practice module (built-in 4 multiple-choice questions, with prompts for correct and wrong choices) 4. Design layout: There are multiple-choice questions and calculation questions, each of which is scored, and the correct answer and score will be displayed after submission B. Gas fire extinguishing system 1. System overview: Overview of gas fire extinguishing system 2. Equipment cognition: It is equipped with the best viewing angle, equipment det*ls (displaying the introduction or parameters of the equipment), practice (built-in 8 multiple-choice questions, with prompts for correct and wrong choices), schematic diagram (you can enter the equipment from the schematic diagram). The equipment includes: nozzle, HFC-227 storage bottle, bottle head valve, heptafluoropropane check valve, high-pressure hose, gas check valve, safety valve, weighing alarm, electromagnetic starter, selection valve, smoke alarm, fire alarm controller. 3. Principle display: Display the working principle of the gas fire extinguishing system, 3D animation demonstration, 3D model is semi-transparent, and the internal gas can be seen. Equipped with a practice module (3 multiple-choice questions built in, with prompts for correct and incorrect choices) 4. Design layout: There are 6 multiple-choice questions, each with a score, and the correct answer and score will be displayed after submission C. Escape drill: Teaching in the form of fun games, escape from the burning room within a limited time, and wrong choices will directly enter the score interface. Experimental purpose: 1. Understand the structure of the heat pipe heat exchanger. 2. The heat transfer coefficient and thermal efficiency of the heat pipe heat exchanger can be calculated. M*n configuration: heat pipe heat exchanger, heating section *r duct, heating section *r duct, fan, Pitot tube flowmeter and differential pressure sensor , heating is steplessly adjusted by a solid pressure regulating module, universal signal input patrol meter displays temperature, pressure difference, ammeter, voltmeter, st*nless steel stand and control screen, etc.

- Previous:zopHGRG-21 gas-liquid two-phase flow experimental platform

- Next:zopHGRG-18 Carbon dioxide P-V-T relationship experimental platform

Recommended Products