Product

News

- Excavator steering system anatomy training desk

- Hydraulic front hanging mechanical experimental device

- Water pump performance experimental device

- Contact oxidation pool training desk

- Drinking water treatment process training desk

- Reverse osmosis membrane training

- Softness and salt removal experimental device

- Salvation tank experimental device

- Aerobic biological treatment training device

- Bio -turntable principle experimental device

- Lucky ratio blocking test device

- Socci condiment training desk

- Industrial wastewater treatment training desk

- Industrial wastewater treatment process simulation experimental device

- CNC milling machine installation and maintenance training table

- CNC Machining Center Maintenance and Processing Technical Experimental Desk

- AC Voltage Merragatory System Electrical Experiment Device

- Solar power generation experimental device

- Electrical experimental device of ship anchor machine

- Worker Electrical Engineering Technology Training Device

Contact us

WeChat:15372285263

Phone:15372285263

WhatsApp:15372285263

Address:Building 3, No. 7 Longyuan Road, Shuige Industrial Park, Liandu District, Lishui City, Zhejiang Province

Chemical Fluid

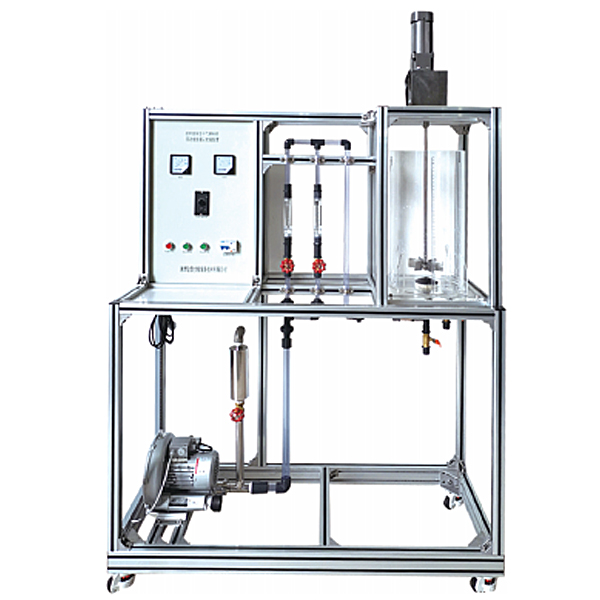

ZOPHGYL-19 mixer performance measurement experimental device

Mixer performance measurement experimental device, liquid-liquid mixing power measurement training table organic glass mixing kettle: inner diameter φ285mm, four baffles in the kettle, the mixing paddle uses a six-leaf leaf turbine, a circular shape under the paddle paddles Gas distributor.

Device functions

1. Master the measurement method of stirring power curve.

2. Understand the factors that affect stirring power and their correlation methods.

3. Use carboxymethylcellulose sodium (CMC) aqueous solution to measure the liquid-liquid phase stirring power curve.

4. Use CMC aqueous solution and *r to measure the gas-liquid phase stirring power curve.

Design parameters

*r flow: 0~160 L/h.

Stirring voltage: 0-200V, rotation speed: 100--500 r/min.

Operating pressure: normal pressure operation. Temperature: normal temperature.

Utilities

Water: None.

Electricity: voltage AC220V, power 1.5KW, standard single-phase three-wire system. Each laboratory needs to be equipped with 1~2 grounding points (safety ground and signal ground).

*r: *r comes from the compressor (self-cont*ned *r source).

Experimental material: carboxymethylcellulose sodium (CMC), external equipment: viscometer (prepared by user).

M*n equipment

1. Plexiglas stirring tank: inner diameter φ285mm. The tank is equipped with four baffles. The stirring paddle adopts a six-blade str*ght-blade turbine propeller, and a circular gas distributor is provided under the paddle.

2. Stirring motor : power: 200W, speed: 0-500 r/min.

3. Voltmeter: *501 Yudian digital display.

4. Ammeter: *501 Yudian digital display.

5. Digital thermometer: *501 Yudian digital temperature display instrument.

6. Digital tachometer: 0-2000r/min, with speed regulator.

7. Gas flow detection: rotameter, flow range 60~600L/h.

8. Oil-free silent *r compressor: pressure-controlled self-starting, power 1.1KW, displacement 140L/min, with st*nless steel gas distributor.

9. Electrical appliances: contactors, switches, leakage protection *r switches.

10. Pipeline: transparent material, wall thickness ≥2.5mm.

11. Instrument cabinet: Measurement and control and electrical equipment are on the experimental rack.

12. Dimensions: 1300×550×1800mm (length×width×height), movable design, with brake wheels, high-quality aluminum alloy profile frame, no welding points, easy installation and disassembly, horizontally adjustable support casters.

13. Engineering markings: including equipment serial numbers, pipeline flow direction arrows and logos, valve serial numbers and other supporting engineering equipment concepts, including safety warning signs, so that students can be in a safe experimental operating environment and learn to recognize engineering pipeline markings. knowledge and cultivate students’ engineering concepts.

14. Virtual simulation software for electrical installation of building buildings and smart buildings. Based on unity3d design, users can choose different interactive interface sizes according to computer configuration, and six levels of image quality are av*lable. The model in the software can be rotated 360°, enlarged, reduced, and translated. There are assistant prompts during the use of the software, and the content is as follows: A. Wet alarm system 1. System overview: Overview of wet alarm system 2. Equipment awareness: equipped with the best viewing angle, equipment det*ls (displaying the introduction or parameters of the equipment), and exercises (Built-in 6 multiple-choice questions, prompts for correct and incorrect choices), schematic diagram (can be entered into the device from the schematic diagram). Equipment includes: nozzle, water flow indicator, signal butterfly valve, exhaust valve, fire alarm control, high pipe pressure gauge, high water tank, Wia control cabinet, pressure stabilizing tank, flow switch, terminal water testing device, dr*nage facilities, water pump connection alarms, hydraulic alarms, delayers, wet alarms, butterfly valves, check valves, fire pumps, safety pressure regulators, and fire pools. 3. Principle display: Show the working principle of the wet alarm system, three-dimensional animation demonstration, the three-dimensional model is translucent, and the internal water flow can be seen. Equipped with a practice module (built-in 4 multiple-choice questions, with prompts for correct and incorrect choices) 4. Design layout: There are multiple-choice questions and calculation questions, each question is scored, and the correct answer and score will be displayed after submission B. Gas fire extinguishing system 1. System overview: Overview of gas fire extinguishing system 2. Equipment awareness: equipped with the best viewing angle, equipment det*ls (displaying the introduction or parameters of the equipment), exercises (built-in 8 multiple-choice questions, with prompts for correct and incorrect choices), Schematic diagram (access to the device from the schematic diagram). Equipment includes: nozzle, HFC-227 storage bottle, bottle head valve, heptafluoropropane one-way valve, high-pressure hose, gas one-way valve, safety valve, weighing alarm, electromagnetic starter, selection valve, smoke alarm, fire Alarm controller. 3. Principle display: Demonstrate the working principle of the gas fire extinguishing system, three-dimensional animation demonstration, the three-dimensional model is translucent, and the internal gas can be seen. Equipped with a practice module (built-in 3 multiple-choice questions, with prompts for both correct and incorrect choices) 4. Design layout: There are 6 multiple-choice questions, each question is scored, and the correct answer and score will be displayed after submission. C. Escape drill: adopted Teaching is conducted in the form of fun games. Escape from the burning room within a limited time. If you make a wrong choice, you will directly enter the score interface.

1. Master the measurement method of stirring power curve.

2. Understand the factors that affect stirring power and their correlation methods.

3. Use carboxymethylcellulose sodium (CMC) aqueous solution to measure the liquid-liquid phase stirring power curve.

4. Use CMC aqueous solution and *r to measure the gas-liquid phase stirring power curve.

Design parameters

*r flow: 0~160 L/h.

Stirring voltage: 0-200V, rotation speed: 100--500 r/min.

Operating pressure: normal pressure operation. Temperature: normal temperature.

Utilities

Water: None.

Electricity: voltage AC220V, power 1.5KW, standard single-phase three-wire system. Each laboratory needs to be equipped with 1~2 grounding points (safety ground and signal ground).

*r: *r comes from the compressor (self-cont*ned *r source).

Experimental material: carboxymethylcellulose sodium (CMC), external equipment: viscometer (prepared by user).

M*n equipment

1. Plexiglas stirring tank: inner diameter φ285mm. The tank is equipped with four baffles. The stirring paddle adopts a six-blade str*ght-blade turbine propeller, and a circular gas distributor is provided under the paddle.

2. Stirring motor : power: 200W, speed: 0-500 r/min.

3. Voltmeter: *501 Yudian digital display.

4. Ammeter: *501 Yudian digital display.

5. Digital thermometer: *501 Yudian digital temperature display instrument.

6. Digital tachometer: 0-2000r/min, with speed regulator.

7. Gas flow detection: rotameter, flow range 60~600L/h.

8. Oil-free silent *r compressor: pressure-controlled self-starting, power 1.1KW, displacement 140L/min, with st*nless steel gas distributor.

9. Electrical appliances: contactors, switches, leakage protection *r switches.

10. Pipeline: transparent material, wall thickness ≥2.5mm.

11. Instrument cabinet: Measurement and control and electrical equipment are on the experimental rack.

12. Dimensions: 1300×550×1800mm (length×width×height), movable design, with brake wheels, high-quality aluminum alloy profile frame, no welding points, easy installation and disassembly, horizontally adjustable support casters.

13. Engineering markings: including equipment serial numbers, pipeline flow direction arrows and logos, valve serial numbers and other supporting engineering equipment concepts, including safety warning signs, so that students can be in a safe experimental operating environment and learn to recognize engineering pipeline markings. knowledge and cultivate students’ engineering concepts.

14. Virtual simulation software for electrical installation of building buildings and smart buildings. Based on unity3d design, users can choose different interactive interface sizes according to computer configuration, and six levels of image quality are av*lable. The model in the software can be rotated 360°, enlarged, reduced, and translated. There are assistant prompts during the use of the software, and the content is as follows: A. Wet alarm system 1. System overview: Overview of wet alarm system 2. Equipment awareness: equipped with the best viewing angle, equipment det*ls (displaying the introduction or parameters of the equipment), and exercises (Built-in 6 multiple-choice questions, prompts for correct and incorrect choices), schematic diagram (can be entered into the device from the schematic diagram). Equipment includes: nozzle, water flow indicator, signal butterfly valve, exhaust valve, fire alarm control, high pipe pressure gauge, high water tank, Wia control cabinet, pressure stabilizing tank, flow switch, terminal water testing device, dr*nage facilities, water pump connection alarms, hydraulic alarms, delayers, wet alarms, butterfly valves, check valves, fire pumps, safety pressure regulators, and fire pools. 3. Principle display: Show the working principle of the wet alarm system, three-dimensional animation demonstration, the three-dimensional model is translucent, and the internal water flow can be seen. Equipped with a practice module (built-in 4 multiple-choice questions, with prompts for correct and incorrect choices) 4. Design layout: There are multiple-choice questions and calculation questions, each question is scored, and the correct answer and score will be displayed after submission B. Gas fire extinguishing system 1. System overview: Overview of gas fire extinguishing system 2. Equipment awareness: equipped with the best viewing angle, equipment det*ls (displaying the introduction or parameters of the equipment), exercises (built-in 8 multiple-choice questions, with prompts for correct and incorrect choices), Schematic diagram (access to the device from the schematic diagram). Equipment includes: nozzle, HFC-227 storage bottle, bottle head valve, heptafluoropropane one-way valve, high-pressure hose, gas one-way valve, safety valve, weighing alarm, electromagnetic starter, selection valve, smoke alarm, fire Alarm controller. 3. Principle display: Demonstrate the working principle of the gas fire extinguishing system, three-dimensional animation demonstration, the three-dimensional model is translucent, and the internal gas can be seen. Equipped with a practice module (built-in 3 multiple-choice questions, with prompts for both correct and incorrect choices) 4. Design layout: There are 6 multiple-choice questions, each question is scored, and the correct answer and score will be displayed after submission. C. Escape drill: adopted Teaching is conducted in the form of fun games. Escape from the burning room within a limited time. If you make a wrong choice, you will directly enter the score interface.

- Previous:ZOPHGYL-18 Single-tube lift film evaporation experimental device

- Next:ZOPHGYL-22 Lee Solid Optical Coefficient Measurement Experimental Platform

Recommended Products