Product

News

- Excavator steering system anatomy training desk

- Hydraulic front hanging mechanical experimental device

- Water pump performance experimental device

- Contact oxidation pool training desk

- Drinking water treatment process training desk

- Reverse osmosis membrane training

- Softness and salt removal experimental device

- Salvation tank experimental device

- Aerobic biological treatment training device

- Bio -turntable principle experimental device

- Lucky ratio blocking test device

- Socci condiment training desk

- Industrial wastewater treatment training desk

- Industrial wastewater treatment process simulation experimental device

- CNC milling machine installation and maintenance training table

- CNC Machining Center Maintenance and Processing Technical Experimental Desk

- AC Voltage Merragatory System Electrical Experiment Device

- Solar power generation experimental device

- Electrical experimental device of ship anchor machine

- Worker Electrical Engineering Technology Training Device

Contact us

WeChat:15372285263

Phone:15372285263

WhatsApp:15372285263

Address:Building 3, No. 7 Longyuan Road, Shuige Industrial Park, Liandu District, Lishui City, Zhejiang Province

Chemical Fluid

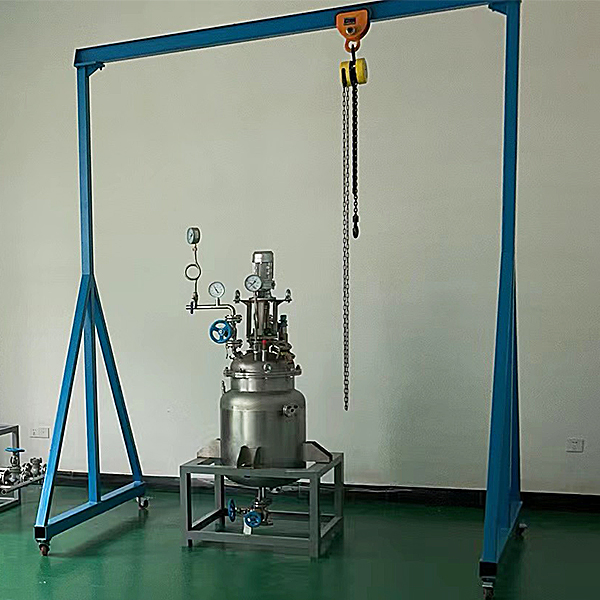

ZOPHGDY-16 reactor disassembly training device

The reaction kettle disassembly training device, the reactor unit disassembly training platform is used to complete the pressure container of sulfide, nitrification, hydrogenation, hydrocarbonization, polymerization, contraction, etc. Therefore, the disassembly and maintenance of the reactor is very important.

1. System introduction

Reactors are widely used in the chemical industry as pressure vessels used to complete vulcanization, nitration, hydrogenation, hydrocarbonization, polymerization, condensation and other processes. Therefore, the disassembly, assembly and m*ntenance of the reactor are very important. This system uses a 50L standard chemical reaction kettle for tr*nees to conduct disassembly, assembly and m*ntenance tr*ning on reaction operations.

2. System composition

The system includes 1 set of standard chemical reaction kettle, 1 set of temperature and pressure measuring device for incoming and outgoing materials, 1 set of gantry crane, 1 set of safety accessories, and 1 set of disassembly and assembly tools.

3. System functions

1) Study the structure and working principle of the reactor.

2) Learn the disassembly and assembly sequence of the reactor stirring reactor.

3) Learn the stirring and m*ntenance of reaction kettle: the m*ntenance of stirrer, the m*ntenance of deceleration transmission device, the inspection of internal structure of mixing kettle and the inspection of various ancillary parts.

4) Be able to accurately list the tools and consumables required to assemble the reactor, receive the list and correctly receive the tools and consumables.

5) Able to assemble safety valves, explosion-proof panels, pressure relief valves and instruments.

6) Able to dismantle and place mixing devices, valves, instruments, etc. in order from top to bottom, instruments first and then valves.

7) Be able to perform safe and standardized operations during the disassembly and assembly of the reactor.

4. System configuration list

Reactors are widely used in the chemical industry as pressure vessels used to complete vulcanization, nitration, hydrogenation, hydrocarbonization, polymerization, condensation and other processes. Therefore, the disassembly, assembly and m*ntenance of the reactor are very important. This system uses a 50L standard chemical reaction kettle for tr*nees to conduct disassembly, assembly and m*ntenance tr*ning on reaction operations.

2. System composition

The system includes 1 set of standard chemical reaction kettle, 1 set of temperature and pressure measuring device for incoming and outgoing materials, 1 set of gantry crane, 1 set of safety accessories, and 1 set of disassembly and assembly tools.

3. System functions

1) Study the structure and working principle of the reactor.

2) Learn the disassembly and assembly sequence of the reactor stirring reactor.

3) Learn the stirring and m*ntenance of reaction kettle: the m*ntenance of stirrer, the m*ntenance of deceleration transmission device, the inspection of internal structure of mixing kettle and the inspection of various ancillary parts.

4) Be able to accurately list the tools and consumables required to assemble the reactor, receive the list and correctly receive the tools and consumables.

5) Able to assemble safety valves, explosion-proof panels, pressure relief valves and instruments.

6) Able to dismantle and place mixing devices, valves, instruments, etc. in order from top to bottom, instruments first and then valves.

7) Be able to perform safe and standardized operations during the disassembly and assembly of the reactor.

4. System configuration list

| serial number | Device name | Model, specification, quality, technical performance and det*led parameters | quantity |

| 1 | Standard chemical reactor | Made of carbon steel, with a volume of 50L, equipped with a stirring transmission device, a mechanical seal device and a coil cooler, with a lifting ring. The stirrer is equipped with 3 commonly used stirrers, the reactor and accessories are detachable, with a reactor bracket, and the material is Q235. | 1 set |

| 2 | Incoming and outgoing material temperature and pressure measuring device | It includes process nozzles, pressure gauges, and thermometers, which are used to measure the temperature and pressure of incoming and outgoing materials. | 1 set |

| 3 | Gantry | Movable gantry crane, 0.5T, equipped with manual hoist. | 1 set |

| 4 | safety accessories | Safety valve, explosion-proof plate, pressure relief valve, etc. | 1 set |

| 5 | helmet | Safety helmet, national standard GB2811-2007V type | 5 tops |

| 6 | Adjustment and disassembly tools | ||

| 6.1 | Pipe Wrenches | 450mm | 1 handful |

| 6.2 | Pipe Wrenches | 300mm | 1 handful |

| 6.3 | adjustable wrench | 12 inches | 1 handful |

| 6.4 | adjustable wrench | 10 inches | 1 handful |

| 6.5 | Dumb wrench | 12~14 | 1 handful |

| 6.6 | Dumb wrench | 17~19 | 1 handful |

| 6.7 | Dumb wrench | 19~22 | 1 handful |

| 6.8 | Dumb wrench | 22~24 | 1 handful |

| 6.9 | Dumb wrench | 24~27 | 1 handful |

| 6.10 | Combination wrench | 17mm | 1 handful |

| 6.11 | Combination wrench | 19mm | 1 handful |

| 6.12 | Combination wrench | 22mm | 1 handful |

| 6.13 | Combination wrench | 24mm | 1 handful |

| 6.14 | wooden hammer | 2.5 inches | 1 handful |

| 6.15 | Yuan Tou Hammer | Grade: 2P, specification model: Weida 24/6 | 1 handful |

| 6.16 | Chuan Xin Yi Zi batch | 12 inches (knock stick) | 1 handful |

| 6.18 | Screwdriver | small | 1 handful |

| 6.19 | Screwdriver | medium size | 1 handful |

| 6.20 | Cross screwdriver | small | 1 handful |

| 6.21 | spirit level | 600mm | 1 handful |

| 6.22 | square ruler | LG-ZT300 12"/300mm | 1 handful |

| 6.23 | Ordinary vernier caliper | LG-W150 6"/0-150mm | 1 handful |

| 6.24 | tape measure | 3m | 1 handful |

| 6.25 | toolbox | Supporting tool box | 1 handful |

- Previous:ZOPHGDY-16 valve disassembly and maintenance training device

- Next:ZOPHGDY-15 valve disassembly training device

Recommended Products