Product

News

- Excavator steering system anatomy training desk

- Hydraulic front hanging mechanical experimental device

- Water pump performance experimental device

- Contact oxidation pool training desk

- Drinking water treatment process training desk

- Reverse osmosis membrane training

- Softness and salt removal experimental device

- Salvation tank experimental device

- Aerobic biological treatment training device

- Bio -turntable principle experimental device

- Lucky ratio blocking test device

- Socci condiment training desk

- Industrial wastewater treatment training desk

- Industrial wastewater treatment process simulation experimental device

- CNC milling machine installation and maintenance training table

- CNC Machining Center Maintenance and Processing Technical Experimental Desk

- AC Voltage Merragatory System Electrical Experiment Device

- Solar power generation experimental device

- Electrical experimental device of ship anchor machine

- Worker Electrical Engineering Technology Training Device

Contact us

WeChat:15372285263

Phone:15372285263

WhatsApp:15372285263

Address:Building 3, No. 7 Longyuan Road, Shuige Industrial Park, Liandu District, Lishui City, Zhejiang Province

Vehicle repair training

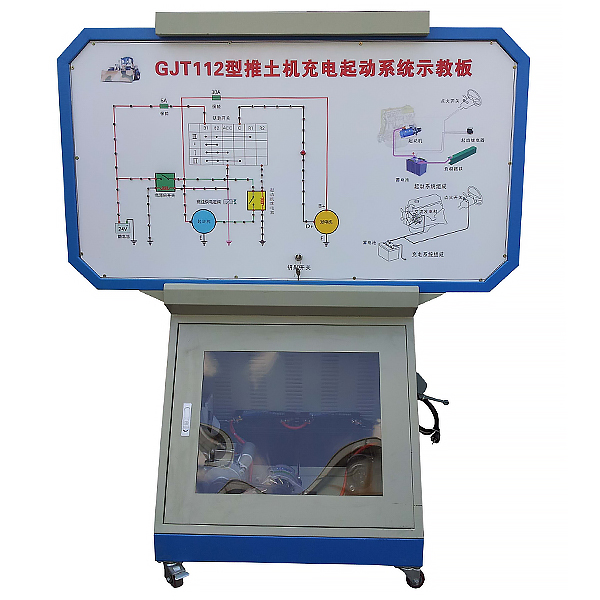

ZOPGC-05 GJT112 Boom Earth Machine Starting and Charging System Training Platform

The bulldozer startup and charging system training desk, the bulldozer startup and charging training device adopt the GJT112 bulldozer start and the physical object of the charging system, fully display the structure and working process of the starting and the charging system.

1. Product Introduction

The equipment is based on the GJT112 bulldozer starting and charging system, which fully demonstrates the composition and working process of the starting and charging system.

It is suitable for the teaching needs of schools on starting and charging system theory and m*ntenance tr*ning.

2. Functional features

1. Real and operational starting and charging system, fully demonstrating the composition and structure of the starting and charging system.

2. Manipulate the starting switch, start the starting motor and generator , and truly demonstrate the working process of the starting and charging system. The changing process of starting current and battery voltage during starting and charging can be observed through the ammeter and voltmeter on the panel.

3. The panel is made of 4mm thick high-grade aluminum-plastic panels that are corrosion-resistant, impact-resistant, pollution-resistant, fire-proof, and moisture-proof. The surface is sprayed with primer using a special process; the panel is printed with a color circuit diagram that will never fade; students can visually compare the circuit diagram and Real objects, understanding and analysis of the working principle of the starting system.

4. The panel is equipped with decomposed parts of the starter and generator assembly, allowing you to intuitively understand the composition of the starter and generator.

5. There are detection terminals installed on the panel, which can directly detect the electrical signals of various circuit components of the starting and charging system, such as resistance, voltage, current, frequency signals, etc.

6. The panel part adopts 1.5mm cold plate stamping structure, with beautiful appearance; the bottom part adopts steel structure welding, and the surface is spray-coated. It has a self-locking caster device. The base is equipped with a tabletop of about 40cm, which is convenient for placing materials and is lightweight. Testing instruments, etc.

7. The steel structure of the tr*ning platform is welded, and the panel box is embedded and fixedly installed; a triangular storage box is set at the bottom and a transparent single door is installed. The surface is spray-coated and equipped with self-locking casters, making it flexible to move, safe, reliable, and durable.

3. Technical specifications

Overall dimensions (approx.): 1600×700×1700mm (length×width×height)

External power supply: AC 220V±10% 50Hz

Working voltage: DC 24V

Working temperature: -40℃~+50℃

Color: 7032

steel pipe : 40*40*3mm

Cabinet: 1.5mm cold plate stamping, with m*ntenance door on the back;

Mobile casters: 100*60mm

4. Basic configuration (each unit)

The equipment is based on the GJT112 bulldozer starting and charging system, which fully demonstrates the composition and working process of the starting and charging system.

It is suitable for the teaching needs of schools on starting and charging system theory and m*ntenance tr*ning.

2. Functional features

1. Real and operational starting and charging system, fully demonstrating the composition and structure of the starting and charging system.

2. Manipulate the starting switch, start the starting motor and generator , and truly demonstrate the working process of the starting and charging system. The changing process of starting current and battery voltage during starting and charging can be observed through the ammeter and voltmeter on the panel.

3. The panel is made of 4mm thick high-grade aluminum-plastic panels that are corrosion-resistant, impact-resistant, pollution-resistant, fire-proof, and moisture-proof. The surface is sprayed with primer using a special process; the panel is printed with a color circuit diagram that will never fade; students can visually compare the circuit diagram and Real objects, understanding and analysis of the working principle of the starting system.

4. The panel is equipped with decomposed parts of the starter and generator assembly, allowing you to intuitively understand the composition of the starter and generator.

5. There are detection terminals installed on the panel, which can directly detect the electrical signals of various circuit components of the starting and charging system, such as resistance, voltage, current, frequency signals, etc.

6. The panel part adopts 1.5mm cold plate stamping structure, with beautiful appearance; the bottom part adopts steel structure welding, and the surface is spray-coated. It has a self-locking caster device. The base is equipped with a tabletop of about 40cm, which is convenient for placing materials and is lightweight. Testing instruments, etc.

7. The steel structure of the tr*ning platform is welded, and the panel box is embedded and fixedly installed; a triangular storage box is set at the bottom and a transparent single door is installed. The surface is spray-coated and equipped with self-locking casters, making it flexible to move, safe, reliable, and durable.

3. Technical specifications

Overall dimensions (approx.): 1600×700×1700mm (length×width×height)

External power supply: AC 220V±10% 50Hz

Working voltage: DC 24V

Working temperature: -40℃~+50℃

Color: 7032

steel pipe : 40*40*3mm

Cabinet: 1.5mm cold plate stamping, with m*ntenance door on the back;

Mobile casters: 100*60mm

4. Basic configuration (each unit)

| serial number | Name | Specifications and models | unit | quantity |

| 1 | Test control panel |

Equipped with various detection terminals, color circuit diagram and working principle diagram (panel: 1200*900*4mm) |

set | 1 |

| 2 | Ignition Switch | brand new | indivual | 1 |

| 3 | Starter assembly | brand new | Only | 1 |

| 3 | dynamo | brand new | Only | 1 |

| 4 | Starter assembly disassembled parts | set | 1 | |

| 5 | Generator assembly disassembled parts | set | 1 | |

| 6 | starter relay | indivual | 1 | |

| 7 | Voltmeter | 0~30V | indivual | 1 |

| 8 | Ammeter | 0~500A | indivual | 1 |

| 9 | battery | 46B24SR, 12V 45Ah, 550CCA | tower | 2 |

| 10 | m*n power switch | 50A | indivual | 1 |

| 11 | R-shaped mobile stand (with self-locking casters) | 1600×700×1700mm (length×width×height) | tower | 1 |

| 12 | Fault simulation and troubleshooting device | set | 1 | |

| 13 | charging indicator | indivual | 1 | |

| 14 | Three-phase asynchronous motor | YT100L1-4 | tower |

1 |

- Previous:ZOPGC-08-round loader vehicle electrical training platform

- Next:ZOPGC-11 Komatsu PC220 excavator full-vehicle electrical electrical control system training platform

Recommended Products