Product

News

- Excavator steering system anatomy training desk

- Hydraulic front hanging mechanical experimental device

- Water pump performance experimental device

- Contact oxidation pool training desk

- Drinking water treatment process training desk

- Reverse osmosis membrane training

- Softness and salt removal experimental device

- Salvation tank experimental device

- Aerobic biological treatment training device

- Bio -turntable principle experimental device

- Lucky ratio blocking test device

- Socci condiment training desk

- Industrial wastewater treatment training desk

- Industrial wastewater treatment process simulation experimental device

- CNC milling machine installation and maintenance training table

- CNC Machining Center Maintenance and Processing Technical Experimental Desk

- AC Voltage Merragatory System Electrical Experiment Device

- Solar power generation experimental device

- Electrical experimental device of ship anchor machine

- Worker Electrical Engineering Technology Training Device

Contact us

WeChat:15372285263

Phone:15372285263

WhatsApp:15372285263

Address:Building 3, No. 7 Longyuan Road, Shuige Industrial Park, Liandu District, Lishui City, Zhejiang Province

Mechanical Basic

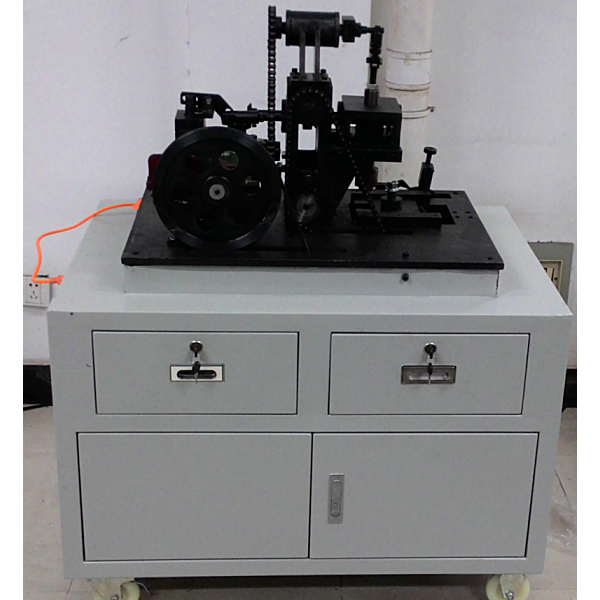

ZOPJX-CCM tooth machine transmission experimental device

The teeth machine transmission experimental desk, the teeth machine teaching experimental equipment adopts a visual design, constructs transparent and intuitive, allows students to be familiar with operation and understand the model structure, transmission action and working principles in a short time.

1. Technical parameters

1. Input power supply: single-phase three-wire AC220V±10% 50Hz;

2. AC speed-regulating motor with deceleration 200W

3. Motor speed 1500r/min

4. Insert knife m=2.5 z=30

5. Blank part: Φ82 ×20, the material requirement is industrial wax.

6. Overall dimensions: 1000×700×1250mm

2. Experimental purposes 1. Understand the structural characteristics and uses of various transmission p*rs of

the gear shaping machine teaching model , and deepen the perceptual and theoretical understanding of various types of mechanical

transmission; 2. Through Assemble and compare different transmission characteristics to improve students' practical ability and innovation awareness, and cultivate students' engineering practice

ability and innovation ability.

3. Deepen the understanding of gear processing by the Fan Cheng method

3. Performance characteristics:

1. This experimental device consists of: knife combination, single-stage spur gear reducer combination, turbine grip reducer combination, shunt combination, tool up and down movement combination, It consists of eight parts, including tool rotating combination, workpiece rotating combination, and supporting cabinet.

2. Tower bottom worm gear reducer transmission module: requires a variety of basic transmission mechanisms , such as: spiral gear mechanism, spur bevel gear mechanism, cam mechanism, crank slider mechanism, crank rocker mechanism, ratchet mechanism, and Belt drive , ch*n drive, slide key combination, etc. can form the transmission system of the gear shaping machine tool, forming a total of five transmission routes of forming motion, cutting motion, feeding motion, and tool yielding motion that coordinate with each other.

3. The craftsmanship is exquisite, the visual design is used, and the structure is transparent and intuitive, allowing students to become familiar with the operation and understand the model structure, transmission action and working principle in a short time.

4. Precautions

1. It is strictly forbidden to start the machine when the gear mesh is not in place.

2. The machine should try to avoid high-speed operation.

3. This model is only for teaching demonstration, for students to observe the internal and external structure.

4. When the machine is out of use, please keep it dust-proof and moisture-proof.

1. Input power supply: single-phase three-wire AC220V±10% 50Hz;

2. AC speed-regulating motor with deceleration 200W

3. Motor speed 1500r/min

4. Insert knife m=2.5 z=30

5. Blank part: Φ82 ×20, the material requirement is industrial wax.

6. Overall dimensions: 1000×700×1250mm

2. Experimental purposes 1. Understand the structural characteristics and uses of various transmission p*rs of

the gear shaping machine teaching model , and deepen the perceptual and theoretical understanding of various types of mechanical

transmission; 2. Through Assemble and compare different transmission characteristics to improve students' practical ability and innovation awareness, and cultivate students' engineering practice

ability and innovation ability.

3. Deepen the understanding of gear processing by the Fan Cheng method

3. Performance characteristics:

1. This experimental device consists of: knife combination, single-stage spur gear reducer combination, turbine grip reducer combination, shunt combination, tool up and down movement combination, It consists of eight parts, including tool rotating combination, workpiece rotating combination, and supporting cabinet.

2. Tower bottom worm gear reducer transmission module: requires a variety of basic transmission mechanisms , such as: spiral gear mechanism, spur bevel gear mechanism, cam mechanism, crank slider mechanism, crank rocker mechanism, ratchet mechanism, and Belt drive , ch*n drive, slide key combination, etc. can form the transmission system of the gear shaping machine tool, forming a total of five transmission routes of forming motion, cutting motion, feeding motion, and tool yielding motion that coordinate with each other.

3. The craftsmanship is exquisite, the visual design is used, and the structure is transparent and intuitive, allowing students to become familiar with the operation and understand the model structure, transmission action and working principle in a short time.

4. Precautions

1. It is strictly forbidden to start the machine when the gear mesh is not in place.

2. The machine should try to avoid high-speed operation.

3. This model is only for teaching demonstration, for students to observe the internal and external structure.

4. When the machine is out of use, please keep it dust-proof and moisture-proof.

- Previous:ZOPYPL-15A pump-cylinder drive closed hydraulic experimental device

- Next:ZOPJX-BX portable electric mechanical combination experimental device

Recommended Products