Product

News

- Excavator steering system anatomy training desk

- Hydraulic front hanging mechanical experimental device

- Water pump performance experimental device

- Contact oxidation pool training desk

- Drinking water treatment process training desk

- Reverse osmosis membrane training

- Softness and salt removal experimental device

- Salvation tank experimental device

- Aerobic biological treatment training device

- Bio -turntable principle experimental device

- Lucky ratio blocking test device

- Socci condiment training desk

- Industrial wastewater treatment training desk

- Industrial wastewater treatment process simulation experimental device

- CNC milling machine installation and maintenance training table

- CNC Machining Center Maintenance and Processing Technical Experimental Desk

- AC Voltage Merragatory System Electrical Experiment Device

- Solar power generation experimental device

- Electrical experimental device of ship anchor machine

- Worker Electrical Engineering Technology Training Device

Contact us

WeChat:15372285263

Phone:15372285263

WhatsApp:15372285263

Address:Building 3, No. 7 Longyuan Road, Shuige Industrial Park, Liandu District, Lishui City, Zhejiang Province

Mechanical Basic

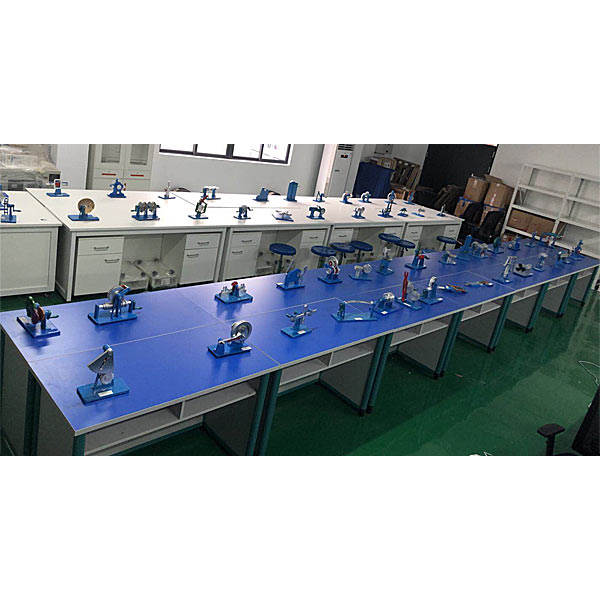

ZOPJXM series mechanical design teaching training device

Mechanical design and teaching model, mechanical part model; thread connection and spiral transmission; with transmission; gear transmission; chain transmission; rolling bearing; coupling shafts and clutch; shaft; key, flower bond, keys without connection and sales.

Used for the "Mechanism Movement Simplified Diagram Surveying and Analysis Experiment" in the mechanical principles course. The workpiece is beautiful and elegant, with high precision in finishing and assembly, and the moving components are flexible and free of interference.

M*n technical parameters:

1. Model material: made of aluminum alloy material or real object.

2. The moving components are mechanically finished, with high installation accuracy and flexible movement of the mechanism.

3. The base plates and brackets of each model are p*nted uniformly, and the moving parts are color-coded to make them beautiful and elegant (if there is a base plate).

Model list:

(1) Threaded connection and screw transmission

(2) Keys, splines, keyless connections and pin connections

(3) Riveting, welding, gluing and interference fit connections

(5) Belt drive

(6)Ch*n drive

(7) Gear transmission

(8) Worm drive

(9) Sliding bearings

(10) Rolling bearings

(11) Couplings and clutches

(12) Axis

M*n technical parameters:

1. Model material: made of aluminum alloy material or real object.

2. The moving components are mechanically finished, with high installation accuracy and flexible movement of the mechanism.

3. The base plates and brackets of each model are p*nted uniformly, and the moving parts are color-coded to make them beautiful and elegant (if there is a base plate).

Model list:

(1) Threaded connection and screw transmission

| serial number | Model name |

| 1 | Single thread right hand thread |

| 2 | Double thread left-hand thread |

| 3 | Three-thread right-hand thread |

| 4 | Commonly used thread thread parts |

| 5 | Ordinary thread; coarse thread and fine thread <cutting> |

| 6 | Three types of cylindrical pipe threads, conical pipe threads, and conical threads (cutting) |

| 7 | Transmission thread: rectangular, trapezoidal, zigzag (cut) |

| 8 | Two types of bolted connections (cutaway) |

| 9 | Two types of double-headed stud and screw connections <cutaway> |

| 10 | Torque measuring wrench |

| 11 | Fixed torque wrench |

| 12 | Three commonly used friction and anti-loosening methods for threaded connections |

| 13 | Three types of mechanical anti-loosening commonly used in threaded connections |

| 14 | Loose bolt connection of lifting hook |

| 15 | Single tight bolt joint stress deformation |

| 16 | Three types of load reducing devices for bolted connections to withstand lateral loads |

| 17 | Sliding Spiral Integral Nut <Cutaway> |

| 18 | screw jack |

| 19 | There are four types of screw transmission: differential screw mechanism, reverse screw mechanism, screw mechanism formation, and screw transmission application |

| serial number | Model name |

| 1 | Three types of ordinary flat key connections <Section> |

| 2 | Guided flat key connection <section> |

| 3 | Two kinds of feather key connection <cutting> |

| 4 | Semicircular key connection <section> |

| 5 | Three types of wedge key connections <section> |

| 6 | Tangential key connection <section> |

| 7 | spline connection |

| 8 | Involute spline, centering according to tooth shape |

| 9 | Two types of profile connections |

| 10 | Three uses of pin connections <Cut> |

| 11 | Shaft end key connection design <cutaway> |

| 12 | Key joint design <section> |

| 13 | Comparison of three types of key and pin connections <Cut> |

| serial number | Model name |

| 1 | Overlap seam riveting <cutaway> |

| 2 | Double cover butt joint riveting <cutaway> |

| 3 | Single cover butt joint riveting <cutaway> |

| 4 | Four types of commonly used rivets after riveting <cutaway> |

| serial number | Model name |

| 1 | Flat belt drive |

| 2 | V-belt drive |

| 3 | Timing belt drive |

| 4 | There are four types of structures of ordinary V-pulleys |

| 5 | Regular belt tensioning slide device |

| 6 | Belt periodic tensioning swing device |

| 7 | automatic belt tensioning device |

| 8 | Tension pulley device |

| serial number | Model name |

| 1 | Single row sleeve roller ch*n drive |

| 2 | Double row sleeve roller ch*n drive |

| 3 | Toothed ch*n drive |

| 4 | There are four types of sprocket structures |

| 5 | Ch*n drive uneven analysis |

| 6 | Ch*n drive automatic tensioning device |

| 7 | Adjustable tensioning device for ch*n drive |

| serial number | Model name |

| 1 | Cylindrical gear shaft |

| 2 | bevel gear shaft |

| 3 | Web structure cylindrical gear |

| 4 | Web-type bevel gear |

| 5 | Spoke-type gears |

| 6 | rack and pinion transmission |

| 7 | Crank bevel gear transmission |

| 8 | Internal spur gear transmission |

| 9 | Helical gear normal section |

| serial number | Model name |

| 1 | Cylindrical worm drive |

| 2 | Arc surface worm drive |

| 3 | Stress analysis of worm drive |

| 4 | Worm drive with heat sink and fan |

| 5 | There are two structural forms of worm |

| 6 | There are four structural forms of worm gears |

| serial number | Model name |

| 1 | split sliding bearings |

| 2 | Integral sliding bearing |

| 3 | Commonly used bearings <set of three> |

| serial number | Model name |

| 1 | 10 categories of rolling bearings (1, 2, 3, 4, 5 single row, 5 double row, 6, 7, N, NA) type <Chrome plated cutaway> |

| 2 | Rolling bearing diameter and width series <3 with the same inner diameter, different widths and different heights, 6 with chrome plating> |

| 3 | Cylindrical spur gear bearing support structure <Bearing formal installation> |

| 4 | Cylindrical helical gear bearing support structure <Bearing reverse installation> |

| 5 | Small bevel gear shaft support structure <Bearing reverse installation> |

| 6 | Small bevel gear shaft support structure <Bearing formal installation> |

| 7 | Worm shaft support structure <Full solid type> |

| 8 | Worm shaft support structure <fixed-swivel type> |

| 9 | Herringbone gear shaft support structure <full travel type> |

| 10 | curved sealing device |

| 11 | Bearing preload device |

| serial number | Model name |

| 1 | Flange coupling <Partial ring centering> |

| 2 | Flange coupling <flange centering> |

| 3 | Cross slide coupling |

| 4 | Cross universal coupling |

| 5 | Gear coupling |

| 6 | Elastic sleeve pin coupling |

| 7 | Flexible pin coupling |

| 8 | Plum blossom shaped elastic coupling |

| 9 | Ratchet overrunning clutch |

| 10 | dog clutch |

| 11 | single disc friction clutch |

| 12 | Multi-disc friction clutch |

| 13 | Teeth type safety clutch |

| serial number | Model name |

| 1 | Shaft structural design process <set of 4 pieces> |

| 2 | Typical shaft parts <set of 4 pieces> |

| 3 | Shaft structure and assembly <Axis positioning one> |

| 4 | Sleeve, round nut, set screw, <axial positioning 2> |

| 5 | Spring ret*ning ring, cone, locking ret*ning ring (Axial Positioning Part 3) |

| 6 | Spline circumferential positioning <Circumferential positioning one> |

| 7 | Interference, keys, screws, etc. <Circumferential Positioning 2> |

| 8 | Circumferential positioning〈3〉 |

| 9 | 8 basic types of commonly used springs |

- Previous:ZOPJXM series mechanical principle drive training device

- Next:ZOPCLB-1 gear pump pump disassembly surveying and mapping training device

Recommended Products