Product

News

- Excavator steering system anatomy training desk

- Hydraulic front hanging mechanical experimental device

- Water pump performance experimental device

- Contact oxidation pool training desk

- Drinking water treatment process training desk

- Reverse osmosis membrane training

- Softness and salt removal experimental device

- Salvation tank experimental device

- Aerobic biological treatment training device

- Bio -turntable principle experimental device

- Lucky ratio blocking test device

- Socci condiment training desk

- Industrial wastewater treatment training desk

- Industrial wastewater treatment process simulation experimental device

- CNC milling machine installation and maintenance training table

- CNC Machining Center Maintenance and Processing Technical Experimental Desk

- AC Voltage Merragatory System Electrical Experiment Device

- Solar power generation experimental device

- Electrical experimental device of ship anchor machine

- Worker Electrical Engineering Technology Training Device

Contact us

WeChat:15372285263

Phone:15372285263

WhatsApp:15372285263

Address:Building 3, No. 7 Longyuan Road, Shuige Industrial Park, Liandu District, Lishui City, Zhejiang Province

Mechanical Basic

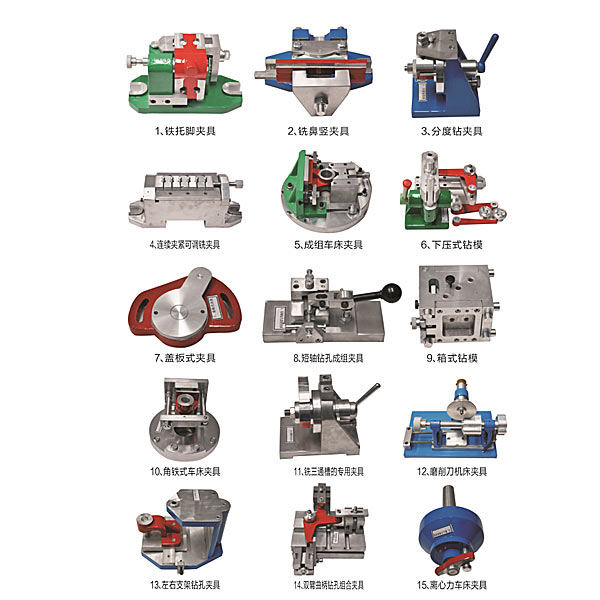

ZOPJXM-JJ machine tool design training device

Machine tool fixture design model, machine tool fixture teaching model iron holding feet, milling nose vertical, dividing drilling fixture continuous clamping can be adjusted, group car tool fixture, lower pressure drilling mold, cover plate type, short shaft drilling group, box, box, box, box, box, box Drilling mold, corner iron lathe fixture.

M*n technical parameters:

1. Model material: made of aluminum alloy material or real object.

2. The moving components are mechanically finished, with high installation accuracy and flexible movement of the mechanism.

3. The base plates and brackets of each model are p*nted uniformly, and the moving parts are color-coded to make them beautiful and elegant (if there is a base plate).

Model list:

1. Model material: made of aluminum alloy material or real object.

2. The moving components are mechanically finished, with high installation accuracy and flexible movement of the mechanism.

3. The base plates and brackets of each model are p*nted uniformly, and the moving parts are color-coded to make them beautiful and elegant (if there is a base plate).

Model list:

| serial number | Model name | Specification | unit price | Remark |

| fixture 1 | Iron bracket clamp | 220×120×160 | 2870 | Aluminum alloy |

| fixture 2 | Milling nose vertical fixture | 210×170×130 | 2960 | Aluminum alloy |

| fixture 3 | Indexing drill fixture | 280×145×230 | 2530 | Aluminum alloy |

| fixture 4 | Continuous clamping adjustable milling fixture | 180×120×150 | 3610 | Aluminum alloy |

| Fixture 5 | Group lathe fixture | φ180×150 | 4410 | Aluminum alloy |

| Fixture 6 | Press down drilling die | φ160×160 | 3680 | Aluminum alloy |

| Fixture 7 | Cover clamp | 280×110×80 | 2380 | Aluminum alloy |

| Fixture 8 | Short axis drilling group fixture | 220×160×100 | 2530 | Aluminum alloy |

| Fixture 9 | Box drilling die | 140×110×120 | 2630 | Aluminum alloy |

| Fixture 10 | Angle iron lathe fixture | 190×170×200 | 6000 | Aluminum alloy |

| Fixture 11 | Special fixture for milling tee slots | 250×200×115 | 4210 | Aluminum alloy |

| Fixture 12 | Grinding tool machine tool fixture | 250×190×140 | 3200 | Aluminum alloy |

| Fixture 13 | Left and right bracket drilling fixture | 200×150×120 | 3710 | Aluminum alloy |

| Fixture 14 | Double arm crank drilling combination fixture | 250×210×150 | 4230 | Aluminum alloy |

| Fixture 15 | Centrifugal force lathe fixture | φ160×280 | 3710 | Aluminum alloy |

| Fixture 16 | Fixed drilling die | 190×120×150 | 2700 | Aluminum alloy |

| Fixture 17 | Rotary drilling die | 180×140×140 | 2870 | Aluminum alloy |

| Fixture 18 | Flip-type drilling die | 160×200×150 | 2700 | Aluminum alloy |

| Fixture 19 | Manual sliding column drilling die | 180×190×210 | 2870 | Aluminum alloy |

| Fixture 20 | Removable drilling template | 260×120×110 | 2700 | Aluminum alloy |

| Fixture 21 | Hanging drill template | 220×170×140 | 3030 | Aluminum alloy |

| Fixture 22 | Elastomeric roller centering clamping lathe fixture | φ180×130 | 4210 | Aluminum alloy |

| Fixture 23 | Linked spiral clamping lathe fixture | φ170×240 | 3980 | Aluminum alloy |

| Fixture 24 | Liquid plastic centering clamping lathe fixture | φ180×210 | 4040 | Aluminum alloy |

| Fixture 25 | Pipe joint group lathe fixture | φ160×300 | 3400 | Aluminum alloy |

| Fixture 26 | Vertical axis rotary indexing drilling machine fixture | φ180×130 | 3400 | Aluminum alloy |

| Fixture 27 | Shift fork group lathe fixture | φ180×270 | 3740 | Aluminum alloy |

| Fixture 28 | Set of lathe fixtures for disc sleeve parts | φ180×210 | 4230 | Aluminum alloy |

| Fixture 29 | Fork fork group lathe fixture | φ180×80 | 4210 | Aluminum alloy |

| Fixture 30 | Hydraulic clamping lathe fixture | φ180×290 | 4380 | Aluminum alloy |

| Fixture 31 | Lathe fixture with indexing device | φ180×140 | 4450 | Aluminum alloy |

| Fixture 32 | Pump body hole lathe fixture | 190×150×120 | 4570 | Aluminum alloy |

| Fixture 33 | Multi-piece clamping lathe fixture | φ170×120 | 4320 | Aluminum alloy |

| Fixture 34 | Disc lathe fixture | φ200×110 | 4330 | Aluminum alloy |

| Clamp 35 | Multi-piece linkage clamping milling machine fixture | 240×120×80 | 5060 | Aluminum alloy |

| Fixture 36 | Pneumatic clamping milling machine fixture | 255×200×170 | 6070 | Aluminum alloy |

| Fixture 37 | Multipurpose milling machine fixture | 250×180×120 | 5320 | Aluminum alloy |

| Fixture 38 | Model milling machine fixture | 200×170×190 | 5320 | Aluminum alloy |

| Fixture 39 | Eccentric clamping milling machine fixture | 230×140×180 | 3640 | Aluminum alloy |

| Clamp 40 | Multi-piece clamping milling machine fixture | 20×140×180 | 5390 | Aluminum alloy |

| Fixture 41 | Liquid plastic multi-piece linkage clamping milling machine fixture | 280×100×110 | 6070 | Aluminum alloy |

| Clamp 42 | Shift fork group milling machine fixture | 200×200×180 | 3710 | Aluminum alloy |

| Fixture 43 | Fork fork group milling machine fixture | 210×170×210 | 3780 | Aluminum alloy |

| Clamp 44 | Oblique linkage clamping milling machine fixture | 240×150×270 | 3780 | Aluminum alloy |

| Clamp 45 | Spiral centering clamping milling machine fixture | 260×180×120 | 4040 | Aluminum alloy |

| Clamp 46 | Semicircular keyway milling machine fixture | 250×150×120 | 3030 | Aluminum alloy |

| Fixture 47 | Milling machine fixture with auxiliary support | 210×150×160 | 3320 | Aluminum alloy |

| Fixture 48 | Linkage clamping milling machine fixture | 270×120×140 | 3540 | Aluminum alloy |

| Fixture 49 | Drilling machine fixture with indexing device | 210×180×130 | 5390 | Aluminum alloy |

| Clamp 50 | Hinged drill press clamp | 250×90×130 | 2700 | Aluminum alloy |

| Fixture 51 | Hanging Drill Template Drilling Machine Clamp | 230×160×160 | 4650 | Aluminum alloy |

| Fixture 52 | Multi-sided flip-up drill press fixture | 140×140×170 | 3540 | Aluminum alloy |

| Fixture 53 | Profile clamp concrete drilling mold | Φ150*170 | 2860 | Aluminum alloy |

| Fixture 54 | Shift fork group drilling machine fixture | 200×130×190 | 3710 | Aluminum alloy |

| Fixture 55 | Universal clamp structure | 290×160×210 | 5060 | Aluminum alloy |

| Fixture 56 | Universal rotary drill press fixture | 330×130×170 | 7410 | Aluminum alloy |

| Fixture 57 | Swing drill press fixture | 185×180×140 | 3880 | Aluminum alloy |

| Fixture 58 | Milling 45 degree milling machine fixture | 280×150×150 | 3300 | Aluminum alloy |

| Fixture 59 | Box boring machine fixture (with rigid boring bar) | 220×150×120 | 5060 | Aluminum alloy |

| Clamp 60 | Double-supported boring machine fixture (with floating boring bar) | 250×190×140 | 5390 | Aluminum alloy |

| Fixture 61 | Group broaching fixture for drawing spline holes (including broaches) | 200×180×150 | 4380 | Aluminum alloy |

| Clamp 62 | Turning combination fixture | φ180×170 | 4040 | Aluminum alloy |

| Fixture 63 | Jig for inspecting part dimensions | 270×200×150 | 3370 | Aluminum alloy |

| Clamp 64 | Jig for inspecting substrate R (with dial indicator) | 220×210×90 | 3710 | Aluminum alloy |

| Clamp 65 | Hole distance inspection fixture (with dial indicator) | 210×120×70 | 4040 | Aluminum alloy |

| Clamp 66 | Clamp for checking coaxiality (with dial indicator) | 230×130×180 | 4380 | Aluminum alloy |

| Fixture 67 | Dovet*l guide r*l parallelism inspection fixture (with dial indicator) | 150×250×150 | 4380 | Aluminum alloy |

| Fixture 68 | Adjustable drilling die for radial holes of shaft parts | 220×180×180 | 3120 | Aluminum alloy |

| Fixture 69 | Vertical boring machine fixture | 300×200×170 | 3900 | Aluminum alloy |

| Clamp 70 | Vertical axis indexing milling fixture | 280×195×210 | 4370 | Aluminum alloy |

| Fixture 71 | Adjustable fixture for grinding convex key shaft | 245×200×220 | 4370 | Aluminum alloy |

| Fixture 72 | Bracket inclined hole drilling die | 240×170×180 | 3850 |

Aluminum alloy |

- Previous:ZOPJXM mechanical drawing test and drawing training device

- Next:ZOPJXM series mechanical principle drive training device

Recommended Products