- Excavator steering system anatomy training desk

- Hydraulic front hanging mechanical experimental device

- Water pump performance experimental device

- Contact oxidation pool training desk

- Drinking water treatment process training desk

- Reverse osmosis membrane training

- Softness and salt removal experimental device

- Salvation tank experimental device

- Aerobic biological treatment training device

- Bio -turntable principle experimental device

- Lucky ratio blocking test device

- Socci condiment training desk

- Industrial wastewater treatment training desk

- Industrial wastewater treatment process simulation experimental device

- CNC milling machine installation and maintenance training table

- CNC Machining Center Maintenance and Processing Technical Experimental Desk

- AC Voltage Merragatory System Electrical Experiment Device

- Solar power generation experimental device

- Electrical experimental device of ship anchor machine

- Worker Electrical Engineering Technology Training Device

WeChat:15372285263

Phone:15372285263

WhatsApp:15372285263

Address:Building 3, No. 7 Longyuan Road, Shuige Industrial Park, Liandu District, Lishui City, Zhejiang Province

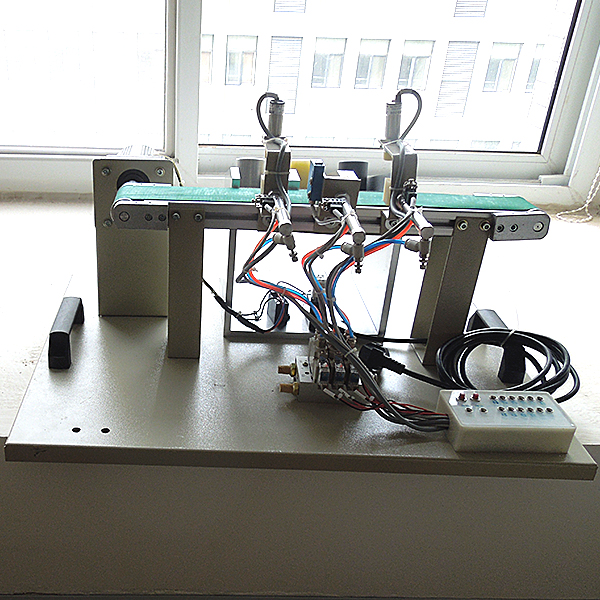

Zoppmx-01 Material Sorting Control Training Device

Material sorting control objects, material sorting PLC control models, instruction switches, photoelectric switches, and indicator components, are connected through terminal rows. The combination of the plug -in connection circuit and the terminal brand connection circuit not only ensure the training of students‘ basic skills.

Equipment structure:

The material sorting control tr*ning model has a metal structure. The I/O terminals of the PLC module, the wiring terminals of the frequency converter, and the connection terminals of each commonly used module are all connected to safety sockets, and wires with safety plugs are used for circuit connections; each The circuits of the command switch, photoelectric switch, and indicating element are connected through the terminal block. The combination of plug-in and pull-out wire connection circuits and terminal card connection circuits not only ensures the tr*ning, formation and consolidation of students' basic skills, but also ensures the speed, safety and reliability of circuit connections.

Technical Parameters

Power supply: single-phase AC220V, 50Hz

Power: <200W

Size: not less than 800*515*220mm

Some practical tr*ning projects:

1. Installation and debugging of pneumatic

system (1) Installation of pneumatic direction control circuit (2) Installation of pneumatic speed control circuit

(3) Installation of pneumatic sequence control circuit (4) Connection of pneumatic system *r circuit

(5) Position adjustment of magnetic switch (6) Pneumatic system debugging

2. Installation and debugging of the frequency converter (frequency converter required)

(1) Connection between the frequency converter and the m*n circuit of the AC motor (2) Parameter setting and operation of the frequency converter panel

(3) Control of the AC motor speed regulation by the frequency converter panel (4) Pass The external terminals of the frequency converter control the start and stop of the motor

3. Installation and debugging of electromechanical equipment ( manipulator required )

(1) Adjustment of coaxiality of transmission device (2) Installation and adjustment of belt conveyor

(3) Installation and debugging of handling robot equipment (4) Installation of object sorting equipment and debugging

(5) Installation and debugging of feeding equipment (6) Installation and debugging of automatic production line equipment (manipulator required)

4. Installation and PLC programming of electrical control circuits

(1) Connection and programming of motor forward and reverse control circuits (2) Connection and programming of motor speed control circuits

(3) Programming of belt conveyor detection (4) Pneumatic sequential action control Program writing

(5) Pneumatic manipulator control program writing (manipulator required) (6) Equipment control program writing

(7) Automatic production line control program writing

5. Installation and debugging of automatic control system

(1) Installation and debugging of various sensors (2) Automatic control of belt conveyor detection

(3) Automatic control of manipulator (manipulator required) (4) Automatic control of mechatronics

(5) Installation and debugging of PLC control system (6) Installation and debugging of automatic production line (need to be equipped with manipulator)

6. It can be used for assessment or skills competition. The professional abilities that can be tested are

(1) Assembly and adjustment ability of mechanical components (2) Installation and debugging ability of electromechanical equipment

(3) Circuit installation ability (4) Installation and debugging ability of pneumatic system

(5) ) Ability to write control programs for mechatronics equipment (6) Ability to install and debug automatic control systems

Hot-selling product: Electrician tr*ning bench

- Previous:Zoppmx-12 Four-axis robot control training device

- Next:Zoppmx-02 Four-layer Elevator Control Training Device