- Excavator steering system anatomy training desk

- Hydraulic front hanging mechanical experimental device

- Water pump performance experimental device

- Contact oxidation pool training desk

- Drinking water treatment process training desk

- Reverse osmosis membrane training

- Softness and salt removal experimental device

- Salvation tank experimental device

- Aerobic biological treatment training device

- Bio -turntable principle experimental device

- Lucky ratio blocking test device

- Socci condiment training desk

- Industrial wastewater treatment training desk

- Industrial wastewater treatment process simulation experimental device

- CNC milling machine installation and maintenance training table

- CNC Machining Center Maintenance and Processing Technical Experimental Desk

- AC Voltage Merragatory System Electrical Experiment Device

- Solar power generation experimental device

- Electrical experimental device of ship anchor machine

- Worker Electrical Engineering Technology Training Device

WeChat:15372285263

Phone:15372285263

WhatsApp:15372285263

Address:Building 3, No. 7 Longyuan Road, Shuige Industrial Park, Liandu District, Lishui City, Zhejiang Province

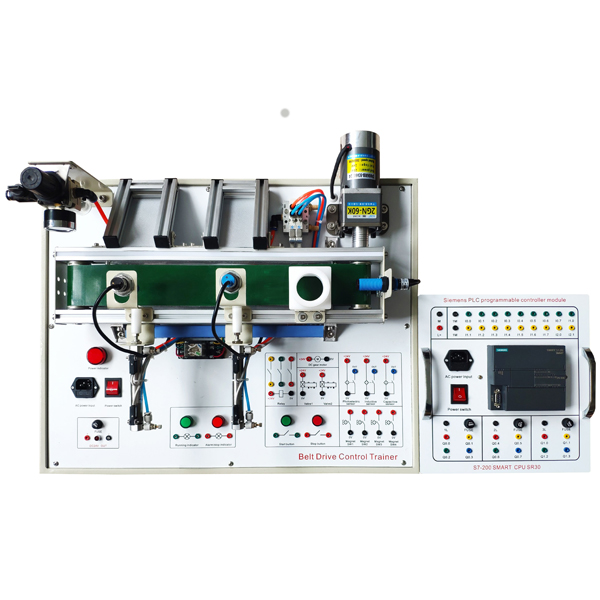

ZOPGJD-FJ material sorting training device

Material sorting training device, material classification experiment table containing pneumatic control, motor transmission, electromagnetic control, location control, sensor detection and other teaching content, is a micro -shrinking device for actual industrial field production equipment.

This experimental equipment should include teaching content such as pneumatic control, motor transmission, electromagnet control, position control, sensor detection, etc. It is a miniature device of actual industrial on-site production equipment. The system should be based on the detection of multiple sensors to achieve the sorting of objects of different materials and colors. It adopts a fully open layout to tr*n the operator's ability in system wiring, mechanical debugging and installation, software programming, independent construction of control systems, feedback setting, fault detection and m*ntenance.

2. Features

1. The equipment device consists of six parts: base plate, tr*ning table (profile structure), pneumatic part, blanking mechanism, material transfer mechanism, material trough and electrical control. The pneumatic part is composed of solenoid valve and cylinder, and the material conveying part is composed of motor and synchronous conveyor belt.

2. Electrical control consists of single-phase AC motor and reducer, solenoid valve, cylinder, switching power supply, photoelectric sensor, capacitive sensor, inductive sensor, magnetic sensor, etc.

3. Through sensor signal collection and PLC programming, the AC motor and solenoid valve are controlled by switching quantity, setting control, and sequential logic control to realize the positioning, identification, and classification of materials on the conveyor belt.

3. Technical parameters

1. Input power supply: single-phase three-wire ~220V±10% 50Hz

2. *r source: 0.2Mpa~0.55Mpa

3. Working environment: temperature -10℃~+40℃ relative humidity ≤85% (25℃) Altitude <4000m

4. Tr*ning device capacity: <0.5KW

4. Device composition

1. The equipment device structure has a profile bottom plate structure

2. The pneumatic part consists of a pressure regulating filter valve, a solenoid valve, a speed regulating valve, a cylinder, a magnetic switch, and an *r pump.

3. The material transfer part is composed of a single-phase AC motor, a reducer and a synchronous belt

. 4. The sensors include photoelectric sensors, capacitive sensors, inductive sensors, magnetic sensors, etc.

5. Practical tr*ning projects

1. Single-phase AC motor forward and reverse rotation control

2 . Sorting out black and white blocks

3. Debugging of material sorting system

4. Sorting out red and white blocks

5. Application of pneumatic control technology

6. Sorting aluminum workpieces to any trough

7. Application of sensor technology

8. Sorting metal workpieces to any trough

9 Application of electromagnet technology

10. Sorting non-metal workpieces to any trough

11. Sorting out metals and non-metals

6. Configuration list

|

Name |

model |

quantity |

unit |

|

PLC |

Shared with experimental bench |

1 |

tower |

|

Motor |

1 |

tower |

|

|

Single rod cylinder |

1 |

indivual |

|

|

Photoelectric switch |

1 |

indivual |

|

|

button |

Φ12 red, green |

2 |

indivual |

|

relay |

24V 20A |

3 |

indivual |

|

DC power supply |

24V 3A |

1 |

indivual |

|

software |

Demonstration board original program and programming software |

1 |

set |

|

manual |

Experiment instructions |

1 |

book |

Hot-selling product: Electrician tr*ning bench

- Previous:ZOPGJD-LK stereo warehouse control training device

- Next:ZOPGJD-02E New Optical Electromechanical Integrity Training Platform